Table of Contents

Benefits of Using a Soup Liquid Filling Sealing Machine Line

Soup liquid filling sealing machine lines are an essential piece of equipment for any food processing facility that produces soups, sauces, or other liquid products. These machines are designed to efficiently fill containers with liquid product, seal them securely, and prepare them for distribution. There are many benefits to using a soup liquid filling sealing machine line, including increased efficiency, improved product quality, and reduced labor costs.

One of the primary benefits of using a soup liquid filling sealing machine line is the increased efficiency it provides. These machines are capable of filling and sealing hundreds of containers per minute, far surpassing the speed at which manual laborers could perform the same task. This increased efficiency allows food processing facilities to produce more product in less time, ultimately increasing their output and profitability.

In addition to increased efficiency, soup liquid filling sealing machine lines also improve product quality. These machines are designed to fill containers with precise amounts of liquid product, ensuring consistency across all containers. This level of precision is difficult to achieve with manual labor, where human error can lead to inconsistencies in product quality. By using a soup liquid filling sealing machine line, food processing facilities can ensure that every container is filled with the correct amount of product, leading to a more consistent and high-quality end product.

Another benefit of using a soup liquid filling sealing machine line is the reduction in labor costs. These machines are capable of performing tasks that would typically require multiple laborers, such as filling and sealing containers. By automating these processes, food processing facilities can reduce their reliance on manual labor, ultimately saving money on wages and increasing their overall profitability. Additionally, using a soup liquid filling sealing machine line can help reduce the risk of workplace injuries associated with repetitive tasks, further lowering labor costs for food processing facilities.

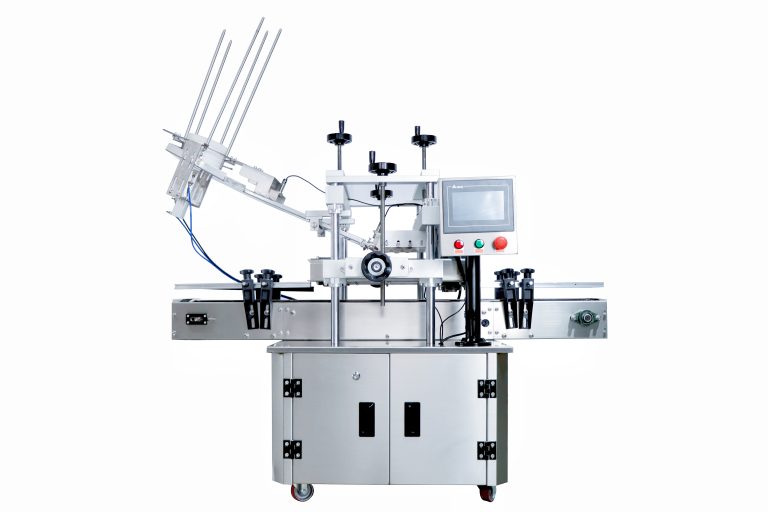

Furthermore, soup liquid filling sealing machine lines are versatile pieces of equipment that can be customized to meet the specific needs of a food processing facility. These machines can be adjusted to fill containers of various sizes and shapes, making them suitable for a wide range of liquid products. Additionally, soup liquid filling sealing machine lines can be integrated with other equipment, such as labeling machines or packaging machines, to create a fully automated production line. This level of customization and integration allows food processing facilities to streamline their production processes and maximize efficiency.

In conclusion, soup liquid filling sealing machine lines offer numerous benefits to food processing facilities, including increased efficiency, improved product quality, reduced labor costs, and versatility. By investing in a soup liquid filling sealing machine line, food processing facilities can streamline their production processes, increase their output, and ultimately improve their profitability. These machines are essential for any food processing facility that produces liquid products and are a worthwhile investment for any business looking to improve their production processes.

How to Choose the Right Soup Liquid Filling Sealing Machine Line for Your Production Needs

Soup liquid filling sealing machine lines are essential equipment for food production companies that specialize in producing soups, sauces, and other liquid products. These machines are designed to efficiently fill containers with liquid products, seal them securely, and prepare them for distribution. Choosing the right soup liquid filling sealing machine line for your production needs is crucial to ensuring the quality and efficiency of your operations.

When selecting a soup liquid filling sealing machine line, there are several factors to consider. One of the most important factors is the production capacity of the machine line. You will need to determine the volume of liquid products you plan to produce on a daily basis and choose a machine line that can meet your production requirements. It is essential to select a machine line that can handle the volume of liquid products you need to produce without causing bottlenecks or delays in your production process.

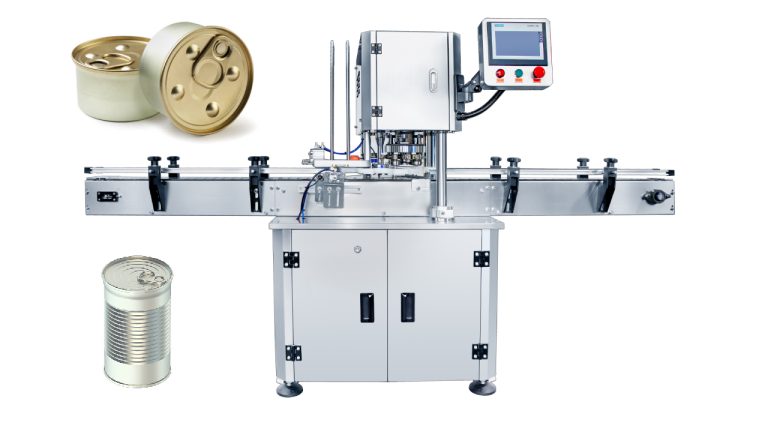

Another important factor to consider when choosing a soup liquid filling sealing machine line is the type of containers you will be using. Different machine lines are designed to fill and seal different types of containers, such as bottles, jars, pouches, or cans. It is essential to choose a machine line that is compatible with the containers you plan to use in your production process to ensure that the filling and sealing process is efficient and accurate.

In addition to production capacity and container compatibility, it is also essential to consider the level of automation and customization options available with the soup liquid filling sealing machine line. Some machine lines offer fully automated processes, while others may require more manual intervention. Depending on your production needs and budget, you may choose a machine line that offers a high level of automation or one that allows for more customization and flexibility in the filling and sealing process.

Furthermore, it is crucial to consider the quality and reliability of the soup liquid filling sealing machine line. You will want to choose a machine line from a reputable manufacturer that has a track record of producing high-quality equipment. It is essential to ensure that the machine line is durable, easy to maintain, and capable of consistently producing high-quality filled and sealed containers.

When selecting a soup liquid filling sealing machine line, it is also important to consider the space available in your production facility. Some machine lines are larger and require more space to operate, while others are more compact and can fit into smaller production areas. It is essential to choose a machine line that fits comfortably within your production facility and allows for efficient workflow and operation.

In conclusion, choosing the right soup liquid filling sealing machine line for your production needs is essential to the success of your food production operations. By considering factors such as production capacity, container compatibility, automation level, quality, reliability, and space requirements, you can select a machine line that meets your specific requirements and helps you produce high-quality liquid products efficiently and effectively. Investing in a high-quality soup liquid filling sealing machine line is a crucial step towards optimizing your production process and ensuring the success of your food production business.