Double-head vacuum capping machines have emerged as a revolutionary solution in the packaging industry, offering significant benefits in terms of time savings and waste reduction. Let’s take a closer look at how these machines achieve these crucial advantages.

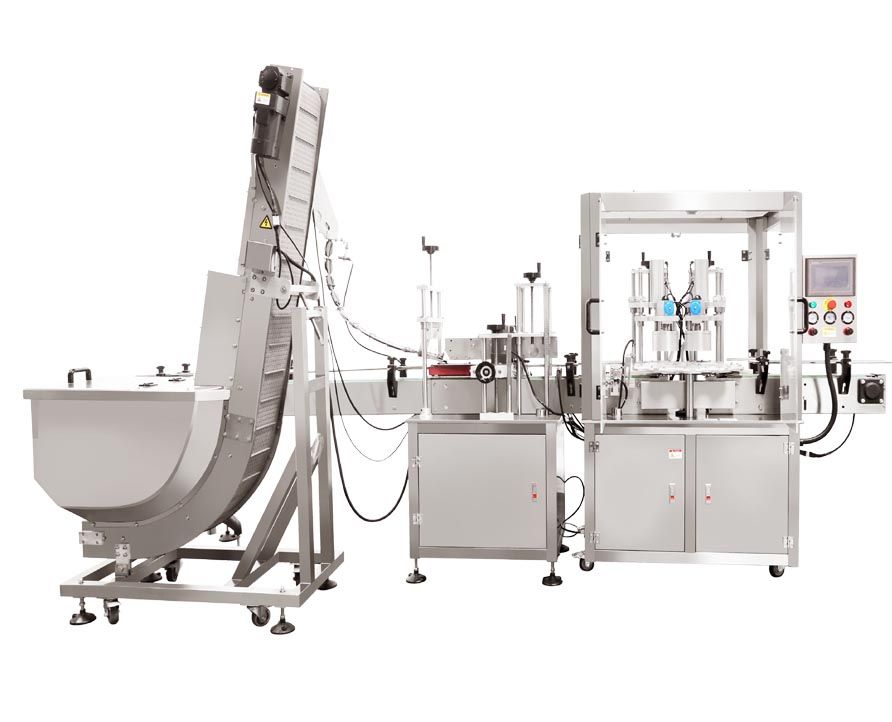

The dual-head design is the primary factor that expedites the capping process. By operating on two bottles simultaneously, these machines effectively double the output rate compared to single-head alternatives. This means that a larger number of bottles can be capped in a shorter period, reducing the overall packaging time and increasing productivity.

The vacuum sealing feature plays a crucial role in minimizing waste. By creating a vacuum inside the bottles before capping, it ensures a tight and secure seal that prevents leakage and spoilage. This leads to a significant reduction in product loss due to damaged or compromised packaging.

The precision and accuracy of double-head vacuum capping machines also contribute to waste reduction. The consistent and reliable application of caps ensures that each bottle is properly sealed, reducing the number of rejected or defective packages. This not only saves resources but also lowers the costs associated with rework and waste disposal.

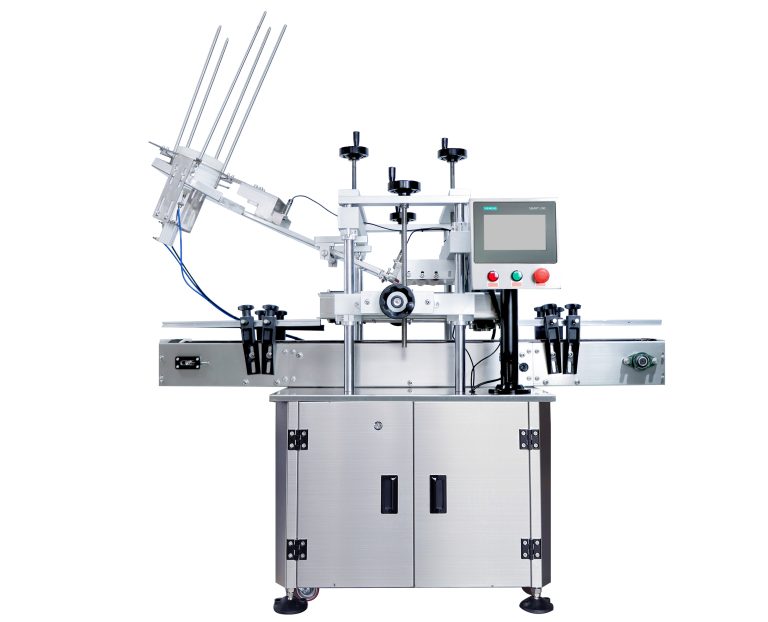

Moreover, these machines are often equipped with advanced control systems that optimize the capping process. They can automatically adjust parameters based on bottle size and cap type, minimizing errors and maximizing efficiency. This intelligent operation helps to avoid unnecessary delays and waste caused by incorrect settings.

The speed and efficiency of double-head vacuum capping machines also allow for seamless integration into production lines. This smooth workflow reduces idle time and bottlenecks, further enhancing productivity and minimizing the potential for waste accumulation.

In conclusion, double-head vacuum capping machines are a game-changer in the packaging sector. Their ability to save time through increased output and reduce waste through superior sealing and precise operation makes them an invaluable asset for businesses seeking to improve efficiency and sustainability in their packaging processes.