Benefits of Using a Fully Automatic Tinplate Can Waterproof Closing Machine

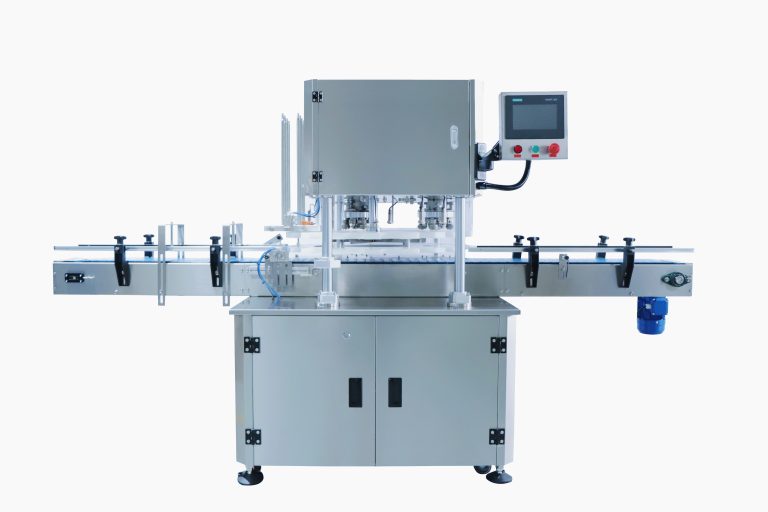

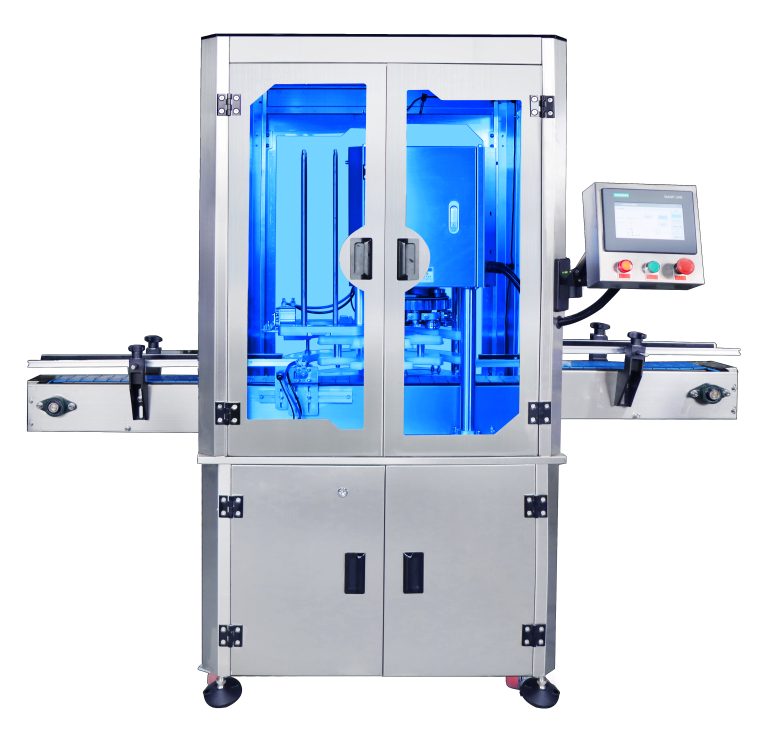

Fully Automatic Tinplate Can Waterproof Closing Machine

In the world of manufacturing, efficiency and precision are key factors in ensuring the success of a business. One piece of equipment that can greatly improve the production process is a fully automatic tinplate can waterproof closing machine. This machine is designed to seal tinplate cans with a waterproof seal, ensuring that the contents inside remain fresh and protected from external elements. There are several benefits to using a fully automatic tinplate can waterproof closing machine, which we will explore in this article.

First and foremost, one of the main benefits of using a fully automatic tinplate can waterproof closing machine is the increase in production efficiency. With this machine, cans can be sealed quickly and accurately, reducing the time and labor required to seal cans manually. This means that more cans can be sealed in a shorter amount of time, leading to increased productivity and ultimately, higher profits for the business.

Additionally, a fully automatic tinplate can waterproof closing machine ensures consistency in the sealing process. Manual sealing can be prone to human error, resulting in uneven seals or leaks that can compromise the quality of the product inside the can. With a fully automatic machine, each can is sealed with the same level of precision and accuracy, ensuring that the contents inside are properly protected.

Furthermore, using a fully automatic tinplate can waterproof closing machine can also improve the overall quality of the sealed cans. The machine is designed to apply the perfect amount of pressure to create a tight seal, preventing any leaks or contamination from occurring. This means that the product inside the can will remain fresh and safe for a longer period of time, increasing its shelf life and reducing the risk of spoilage.

Another benefit of using a fully automatic tinplate can waterproof closing machine is the reduction in waste. When cans are sealed manually, there is a higher chance of errors occurring, leading to a higher rate of rejected cans that cannot be sold. With a fully automatic machine, the risk of errors is significantly reduced, resulting in fewer rejected cans and less waste overall.

In addition to these benefits, a fully automatic tinplate can waterproof closing machine is also easy to operate and maintain. Once the machine is set up and calibrated, it can run continuously with minimal supervision, freeing up workers to focus on other tasks. Maintenance is also simple, with regular cleaning and lubrication ensuring that the machine continues to operate smoothly and efficiently.

In conclusion, a fully automatic tinplate can waterproof closing machine offers a wide range of benefits for businesses in the manufacturing industry. From increased production efficiency and consistency to improved quality and reduced waste, this machine is a valuable asset that can help businesses streamline their production process and improve their bottom line. By investing in a fully automatic tinplate can waterproof closing machine, businesses can ensure that their products are sealed securely and protected from external elements, ultimately leading to greater success and profitability.