Table of Contents

Benefits of Using Milk Powder in Baking Recipes

Milk powder is a versatile ingredient that can be used in a variety of baking recipes to enhance flavor, texture, and moisture. One of the key benefits of using milk powder in baking is its convenience and long shelf life. Milk powder can be stored for extended periods of time without spoiling, making it a convenient pantry staple for home bakers and commercial bakeries alike.

In addition to its long shelf life, milk powder offers a number of practical advantages when it comes to baking. For one, milk powder is easy to measure and incorporate into recipes, as it can be easily reconstituted with water to create liquid milk. This eliminates the need to keep fresh milk on hand, which can be a hassle for some bakers. Milk powder also helps to improve the structure and texture of baked goods, resulting in a more consistent and uniform product.

Another benefit of using milk powder in baking is its ability to enhance the flavor of baked goods. Milk powder contains natural milk proteins and sugars that contribute to a rich, creamy flavor in baked goods. This can be especially beneficial in recipes that call for a subtle dairy flavor, such as scones, biscuits, and muffins. By using milk powder, bakers can achieve a more pronounced dairy flavor without adding extra liquid to the recipe.

Furthermore, milk powder can help to improve the moisture content of baked goods, resulting in a softer, more tender crumb. This is particularly useful in recipes that tend to dry out quickly, such as breads, cakes, and cookies. By incorporating milk powder into the recipe, bakers can ensure that their baked goods stay moist and fresh for longer periods of time.

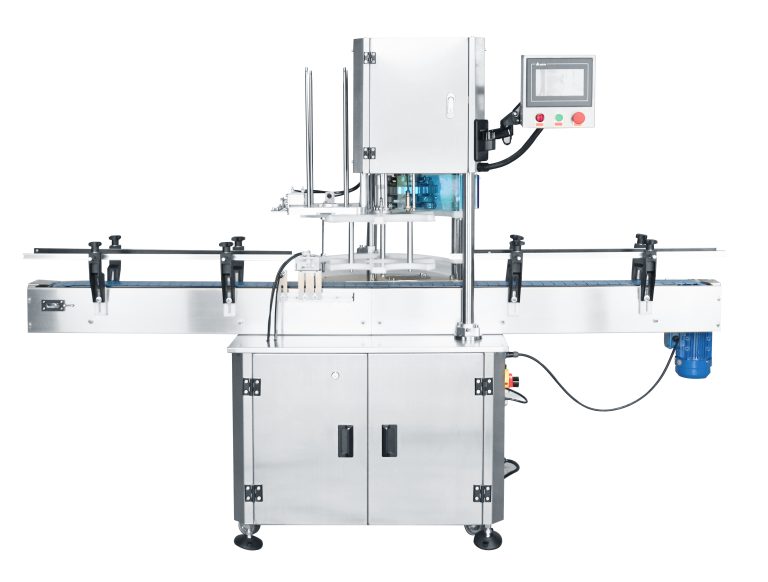

One of the challenges of using milk powder in baking is ensuring that it is properly sealed and stored to maintain its freshness and quality. Vacuum nitrogen sealing machines offer a solution to this problem by providing an airtight seal that helps to preserve the flavor and texture of the milk powder. These machines remove oxygen from the packaging and replace it with nitrogen gas, which helps to prevent oxidation and spoilage.

By using a vacuum nitrogen sealing machine, bakers can extend the shelf life of their milk powder and ensure that it remains fresh and flavorful for longer periods of time. This can be especially beneficial for commercial bakeries that need to store large quantities of milk powder for extended periods of time. By investing in a vacuum nitrogen sealing machine, bakeries can reduce waste and save money by extending the shelf life of their ingredients.

In conclusion, milk powder is a versatile ingredient that offers a number of benefits when used in baking recipes. From its convenience and long shelf life to its ability to enhance flavor, texture, and moisture in baked goods, milk powder is a valuable ingredient for bakers of all skill levels. By using a vacuum nitrogen sealing machine to properly store and preserve milk powder, bakers can ensure that their ingredients remain fresh and flavorful for longer periods of time.

How Vacuum Nitrogen Sealing Machines Extend the Shelf Life of Milk Powder

Milk powder is a popular dairy product that has a long shelf life when stored properly. One of the key factors in maintaining the quality and freshness of milk powder is the packaging process. Vacuum nitrogen sealing machines play a crucial role in extending the shelf life of milk powder by removing oxygen from the packaging and replacing it with nitrogen gas.

When milk powder is exposed to oxygen, it can lead to oxidation, which can cause the milk powder to spoil more quickly. By using vacuum nitrogen sealing machines, manufacturers can create a controlled environment inside the packaging that helps to preserve the quality of the milk powder for a longer period of time.

The process of vacuum nitrogen sealing involves removing the air from the packaging and replacing it with nitrogen gas. This creates a low-oxygen environment that helps to prevent oxidation and microbial growth, which can lead to spoilage. The nitrogen gas also acts as a barrier to moisture and light, further protecting the milk powder from degradation.

Vacuum nitrogen sealing machines are designed to create a tight seal on the packaging, ensuring that no air can enter and compromise the quality of the milk powder. This airtight seal helps to maintain the freshness of the milk powder and extend its shelf life significantly.

In addition to extending the shelf life of milk powder, vacuum nitrogen sealing machines also help to preserve the nutritional value of the product. Oxygen can cause the degradation of vitamins and minerals in milk powder, but by removing oxygen from the packaging, manufacturers can ensure that the nutritional content of the milk powder remains intact.

Furthermore, vacuum nitrogen sealing machines are also beneficial for preventing the growth of bacteria and other harmful microorganisms in milk powder. By creating a low-oxygen environment, these machines help to inhibit the growth of spoilage-causing bacteria, which can lead to foodborne illnesses if consumed.

Overall, vacuum nitrogen sealing machines are an essential tool for ensuring the quality and safety of milk powder. By removing oxygen from the packaging and replacing it with nitrogen gas, these machines help to extend the shelf life of milk powder, preserve its nutritional value, and prevent the growth of harmful bacteria.

In conclusion, vacuum nitrogen sealing machines play a vital role in the packaging process of milk powder. By creating a low-oxygen environment inside the packaging, these machines help to extend the shelf life of milk powder, preserve its nutritional content, and prevent the growth of harmful bacteria. Manufacturers rely on vacuum nitrogen sealing machines to ensure that consumers receive a high-quality and safe product that meets their expectations for freshness and taste.

-768x576.png)