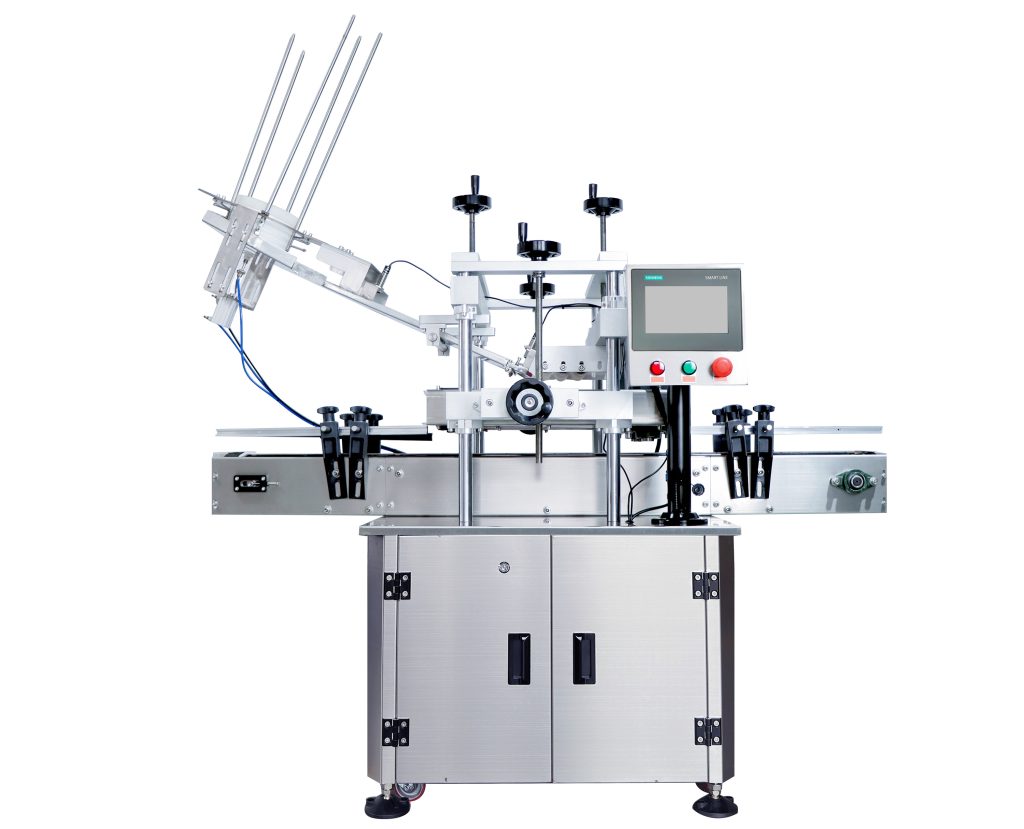

In the world of powder packaging, the automatic powder tin can plastic press lid capping machine is a revolutionary piece of equipment. This advanced machine is specifically designed to handle the capping process of powder-filled tin cans with plastic press lids with precision and speed.

One of the standout features of this capping machine is its automation. It eliminates the need for manual intervention, reducing the risk of human error and increasing the overall efficiency of the packaging line. The machine can cap a large number of tin cans in a short period, allowing for higher production output.

The precision in capping is crucial. The machine ensures that each plastic press lid is securely and evenly attached to the tin can, providing a tight seal that prevents powder leakage and protects the product’s quality. This not only maintains the integrity of the contents but also enhances the shelf life of the packaged powder.

The adaptability of the automatic powder tin can plastic press lid capping machine is another significant advantage. It can handle different sizes and shapes of tin cans and plastic press lids, making it suitable for a wide variety of powder products. This flexibility allows manufacturers to switch between different packaging formats easily, responding quickly to market demands.

The automatic powder tin can plastic press lid capping machine is often equipped with advanced sensors and control systems to monitor the capping process. Any deviations or malfunctions are detected promptly, minimizing waste and ensuring consistent quality in the final packaged products.

Maintenance of the capping machine is relatively straightforward. With proper care and regular servicing, it can operate reliably for an extended period, reducing downtime and maintenance costs.

In conclusion, the automatic powder tin can plastic press lid capping machine is a game-changer in the powder packaging industry. It combines efficiency, precision, adaptability, and reliability to streamline the packaging process and deliver high-quality packaged products to the market.

Stay tuned to our blogs for more in-depth looks and updates on the latest advancements in packaging machinery!