Table of Contents

Benefits of Using a Tape Sealing Machine in Packaging Operations

In the world of packaging operations, efficiency and effectiveness are key factors in ensuring that products are securely packaged and ready for distribution. One tool that has become essential in this process is the tape sealing machine. This machine is designed to quickly and securely seal packages using adhesive tape, providing a reliable and consistent seal that helps to protect the contents of the package during transit.

One of the key benefits of using a tape sealing machine is the speed at which it can seal packages. These machines are designed to work quickly and efficiently, allowing for a high volume of packages to be sealed in a short amount of time. This can help to streamline the packaging process and increase overall productivity, saving time and labor costs in the long run.

In addition to speed, tape sealing machines also provide a consistent and reliable seal on packages. This helps to ensure that packages are securely sealed and protected from damage during shipping and handling. The adhesive tape used in these machines is strong and durable, providing a secure seal that won’t easily come undone. This can help to reduce the risk of packages becoming damaged or lost during transit, ultimately saving time and money for businesses.

Another benefit of using a tape sealing machine is the versatility it offers in packaging operations. These machines can be used to seal a wide range of package sizes and shapes, making them ideal for businesses that package a variety of products. Whether you are sealing small boxes or large packages, a tape sealing machine can handle the job with ease, providing a reliable seal every time.

Furthermore, tape sealing machines are easy to use and require minimal training to operate. This makes them a cost-effective solution for businesses looking to streamline their packaging operations without investing in expensive equipment or extensive training for employees. With a tape sealing machine, anyone can quickly and easily seal packages, helping to increase efficiency and reduce the risk of errors in the packaging process.

Overall, the benefits of using a tape sealing machine in packaging operations are clear. From increased speed and efficiency to reliable and consistent seals, these machines offer a cost-effective solution for businesses looking to improve their packaging processes. With their versatility and ease of use, tape sealing machines are a valuable tool for any business looking to streamline their packaging operations and ensure that their products are securely packaged and ready for distribution.

How to Choose the Right Tape Sealing Machine for Your Business

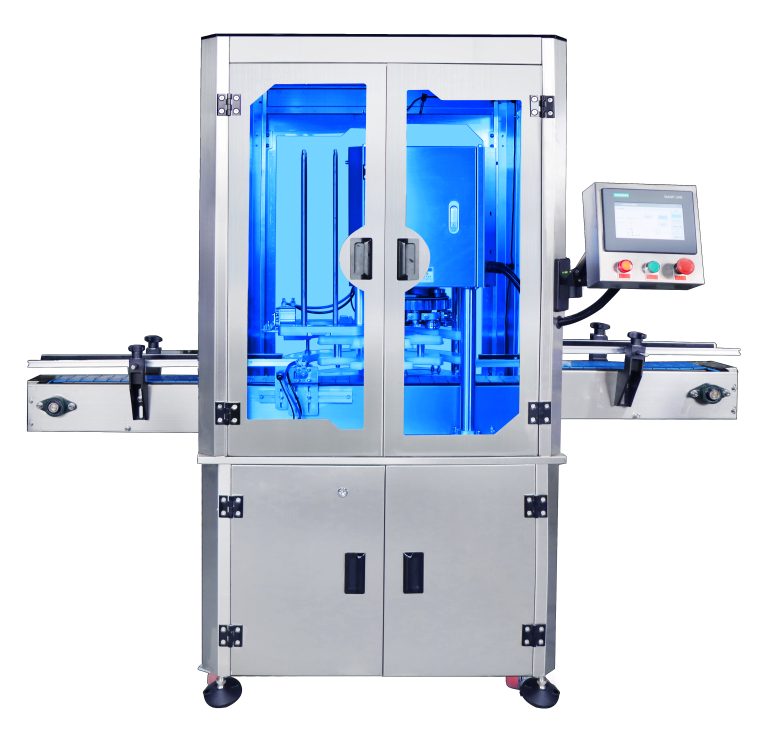

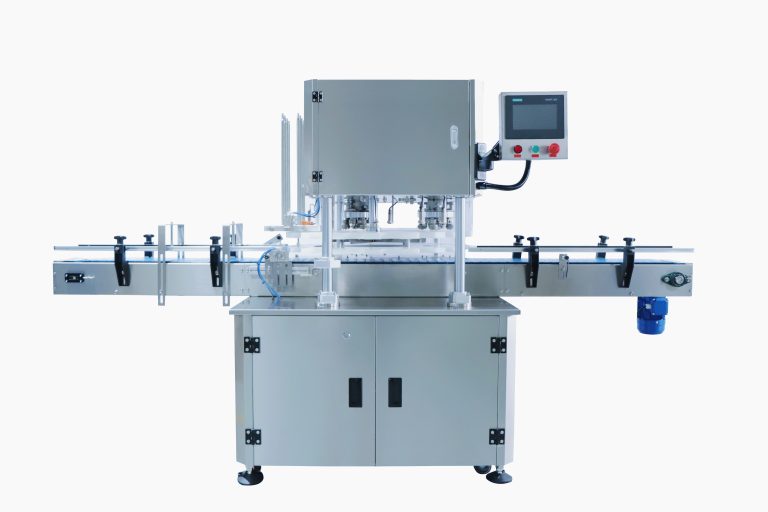

A tape sealing machine is a piece of equipment used in various industries to seal packages and boxes securely. It is an essential tool for businesses that need to ship products or store items in a safe and secure manner. Tape sealing machines come in different sizes and types, each designed for specific packaging needs. When choosing the right tape sealing machine for your business, there are several factors to consider to ensure you get the most suitable equipment for your requirements.

One of the first things to consider when choosing a tape sealing machine is the type of packaging materials you will be using. Different machines are designed to work with specific types of tape, such as pressure-sensitive tape, water-activated tape, or heat-activated tape. It is essential to choose a machine that is compatible with the type of tape you will be using to ensure proper sealing and secure packaging.

Another important factor to consider is the volume of packaging you will be doing. If you have a high volume of packages to seal, you will need a machine that can handle the workload efficiently. Look for a tape sealing machine with a high-speed motor and automatic feeding system to increase productivity and reduce downtime.

The size of the packages you will be sealing is also crucial when choosing a tape sealing machine. Some machines are designed for small packages, while others can handle larger boxes. Make sure to choose a machine that can accommodate the size of your packages to ensure proper sealing and secure packaging.

Consider the space available in your workspace when choosing a tape sealing machine. Some machines are compact and can fit on a tabletop, while others are larger and require more floor space. Measure the available space in your facility and choose a machine that fits comfortably without causing any obstructions.

When choosing a tape sealing machine, it is essential to consider the ease of use and maintenance. Look for a machine that is user-friendly and easy to operate, with clear instructions and controls. Consider the maintenance requirements of the machine, such as cleaning and lubrication, and choose a machine that is easy to maintain to ensure optimal performance and longevity.

Finally, consider the cost of the tape sealing machine and your budget. Compare prices from different manufacturers and suppliers to find a machine that fits within your budget while meeting your requirements. Keep in mind that investing in a high-quality tape sealing machine can save you time and money in the long run by ensuring secure packaging and reducing the risk of damaged goods during shipping.

In conclusion, choosing the right tape sealing machine for your business is essential to ensure secure packaging and efficient operations. Consider factors such as the type of packaging materials, volume of packaging, package size, available space, ease of use and maintenance, and cost when selecting a machine. By taking these factors into account, you can find the most suitable tape sealing machine for your business needs and ensure smooth and secure packaging operations.