Table of Contents

Benefits of Using Automatic Can Sealing Machines

Automatic can sealing machines are a crucial piece of equipment for businesses in the food and beverage industry. These machines offer a fast and efficient way to seal cans, ensuring that products are properly preserved and protected. There are several different types of automatic can sealing machines available on the market, each with its own unique features and benefits. In this article, we will explore the various types of automatic can sealing machines and discuss the benefits of using them in your business.

One of the most common types of automatic can sealing machines is the rotary can seamer. This type of machine is ideal for high-volume production lines, as it can seal a large number of cans quickly and efficiently. Rotary can seamers are designed to handle a wide range of can sizes and can be easily adjusted to accommodate different can diameters. These machines are also highly versatile, allowing businesses to seal cans of various materials, including aluminum and tinplate.

Another popular type of automatic can sealing machine is the vacuum seamer. Vacuum seamers are designed to remove air from the can before sealing, creating a tight seal that helps to preserve the freshness and quality of the product inside. These machines are ideal for sealing perishable goods, such as canned fruits and vegetables, as they help to extend the shelf life of the product. Vacuum seamers are also highly efficient, with some models capable of sealing hundreds of cans per minute.

In addition to rotary and vacuum seamers, businesses can also choose from a range of other automatic can sealing machines, including double seamers, single seamers, and combination seamers. Double seamers are designed to create a double seam on the can, providing an extra layer of protection against leaks and contamination. Single seamers, on the other hand, are ideal for sealing cans with a single seam, such as beverage cans. Combination seamers combine the features of both double and single seamers, offering businesses a versatile and efficient sealing solution.

There are several benefits to using automatic can sealing machines in your business. One of the primary benefits is increased efficiency. Automatic can sealing machines are designed to seal cans quickly and accurately, helping to streamline the production process and reduce labor costs. These machines are also highly reliable, ensuring that each can is sealed to the highest standards of quality and safety.

Another key benefit of using automatic can sealing machines is improved product quality. By sealing cans with precision and consistency, these machines help to maintain the freshness and integrity of the product inside. This is particularly important for perishable goods, as a tight seal can help to prevent spoilage and extend the shelf life of the product. Automatic can sealing machines also help to reduce the risk of contamination, ensuring that products are safe for consumption.

In conclusion, automatic can sealing machines are an essential piece of equipment for businesses in the food and beverage industry. With a variety of types to choose from, including rotary, vacuum, double, single, and combination seamers, businesses can find the perfect sealing solution to meet their needs. By investing in automatic can sealing machines, businesses can enjoy increased efficiency, improved product quality, and enhanced safety and reliability.

Comparison of Different Types of Automatic Can Sealing Machines

Automatic can sealing machines are essential equipment for businesses in the food and beverage industry. These machines help streamline the packaging process by sealing cans quickly and efficiently. There are several types of automatic can sealing machines available on the market, each with its own unique features and capabilities. In this article, we will provide you with a comprehensive guide to the different types of automatic can sealing machines to help you make an informed decision for your business.

One of the most common types of automatic can sealing machines is the rotary can seamer. This type of machine is ideal for high-volume production as it can seal a large number of cans in a short amount of time. Rotary can seamers are equipped with multiple sealing heads that work simultaneously to seal cans efficiently. These machines are highly versatile and can be used to seal cans of various sizes and shapes.

Another popular type of automatic can sealing machine is the inline can seamer. Unlike rotary can seamers, inline can seamers seal cans in a linear fashion, one at a time. These machines are ideal for businesses with lower production volumes or limited space. Inline can seamers are compact and easy to operate, making them a great choice for small to medium-sized businesses.

For businesses that require a more specialized solution, there are also vacuum can seamers available on the market. Vacuum can seamers are designed to seal cans in a vacuum environment, which helps preserve the freshness and quality of the product inside. These machines are commonly used in the food industry for packaging perishable goods such as fruits, vegetables, and seafood.

In addition to the different types of automatic can sealing machines, there are also various sealing methods to consider. The most common sealing method is double seam sealing, which involves folding the lid of the can over the body and crimping it to create a tight seal. This method is widely used in the food and beverage industry for sealing cans of various sizes and materials.

Another sealing method to consider is vacuum sealing, which involves removing the air from the can before sealing it. This method is ideal for preserving the freshness and quality of perishable goods. Vacuum sealing can help extend the shelf life of products and reduce the risk of spoilage.

When choosing an automatic can sealing machine for your business, it is important to consider your production volume, space constraints, and sealing requirements. Rotary can seamers are ideal for high-volume production, while inline can seamers are better suited for businesses with lower production volumes. Vacuum can seamers are a great choice for businesses that require a specialized sealing solution.

In conclusion, automatic can sealing machines are essential equipment for businesses in the food and beverage industry. There are several types of automatic can sealing machines available on the market, each with its own unique features and capabilities. By understanding the different types of automatic can sealing machines and sealing methods, you can make an informed decision for your business and choose the right machine to meet your production needs.

Tips for Choosing the Right Automatic Can Sealing Machine for Your Needs

Automatic can sealing machines are essential equipment for businesses in the food and beverage industry. These machines help to seal cans quickly and efficiently, ensuring that products are properly preserved and protected. However, with so many different types of automatic can sealing machines available on the market, it can be challenging to choose the right one for your specific needs. In this article, we will provide you with a comprehensive guide to the different types of automatic can sealing machines, as well as some tips for selecting the best machine for your business.

One of the most common types of automatic can sealing machines is the rotary can seamer. This type of machine is ideal for high-volume production lines, as it can seal a large number of cans quickly and efficiently. Rotary can seamers are typically used in industries such as canning, brewing, and soft drink production. These machines are capable of sealing cans of various sizes and shapes, making them versatile and adaptable to different production requirements.

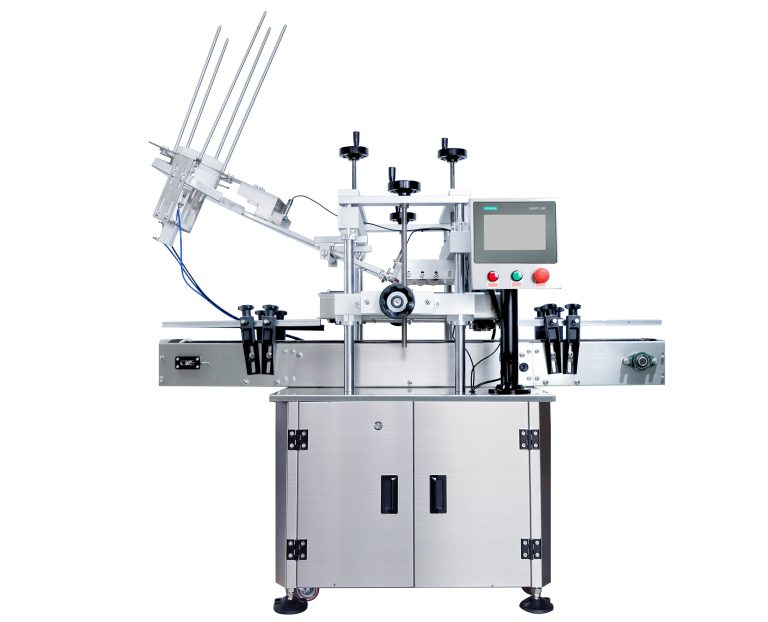

Another popular type of automatic can sealing machine is the inline can seamer. Inline can seamers are designed for smaller production lines or businesses with limited space. These machines are compact and easy to operate, making them ideal for small-scale operations. Inline can seamers are also suitable for sealing cans of different sizes and shapes, making them a versatile option for businesses with diverse product lines.

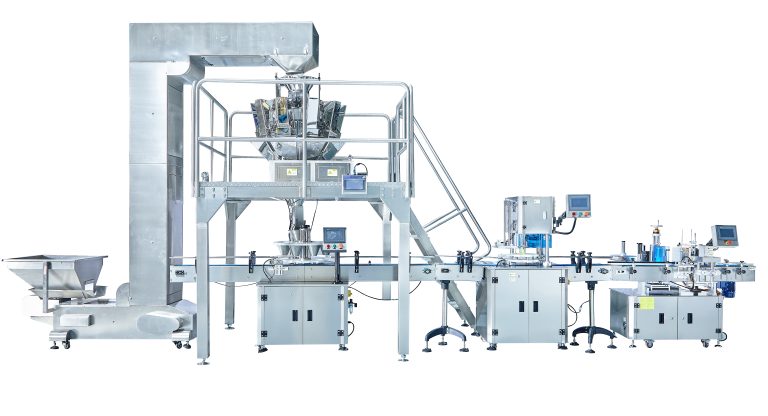

For businesses that require a higher level of automation, there are fully automatic can sealing machines available on the market. These machines are equipped with advanced technology that allows them to seal cans without any human intervention. Fully automatic can sealing machines are ideal for businesses with high production volumes and strict quality control requirements. These machines are capable of sealing cans quickly and accurately, ensuring that products are properly sealed and preserved.

In addition to the different types of automatic can sealing machines, there are also various features and specifications to consider when choosing the right machine for your business. One important factor to consider is the speed of the machine. The speed of a can sealing machine is measured in cans per minute (CPM), and it is essential to select a machine that can meet your production requirements. It is also important to consider the size and shape of the cans that the machine can seal, as well as the type of sealing method used.

When selecting an automatic can sealing machine, it is crucial to consider your specific production needs and requirements. It is essential to choose a machine that is capable of sealing cans quickly and accurately, while also meeting your production volume and quality control standards. It is also important to consider the space available in your production facility, as well as your budget constraints.

In conclusion, automatic can sealing machines are essential equipment for businesses in the food and beverage industry. There are several different types of automatic can sealing machines available on the market, each with its own unique features and specifications. By considering your specific production needs and requirements, as well as the different types of machines available, you can select the right automatic can sealing machine for your business. With the right machine in place, you can ensure that your products are properly sealed and preserved, helping to maintain the quality and freshness of your products.