Benefits of Using Sauce Filler Equipment for Various Types of Sauces

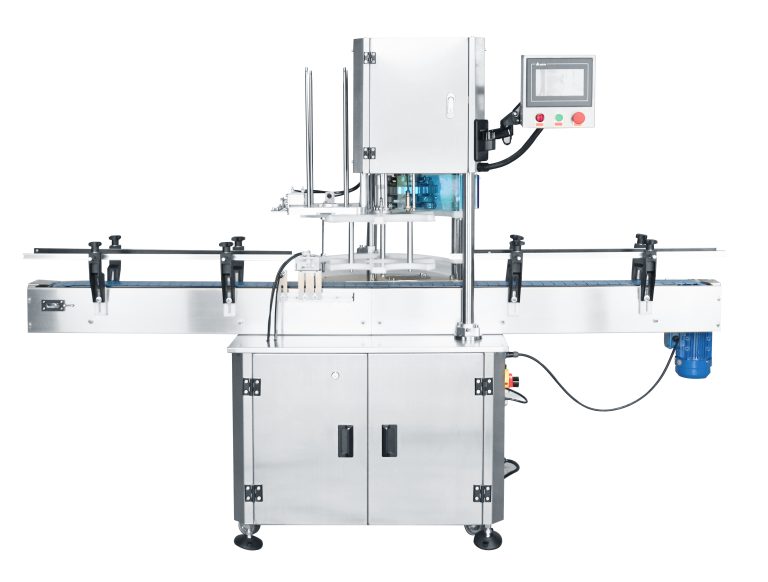

Sauce filler equipment is an essential tool for any food production facility that deals with sauces of all kinds. Whether you are producing ketchup, mayonnaise, mustard, or any other type of sauce, having the right equipment can make a significant difference in the efficiency and quality of your production process.

One of the main benefits of using sauce filler equipment is the ability to accurately measure and dispense the sauce. This ensures that each bottle or container is filled with the correct amount of sauce, eliminating waste and ensuring consistency in the final product. This is especially important for companies that need to meet strict quality control standards and regulations.

Another benefit of using sauce filler equipment is the speed and efficiency it brings to the production process. Manual filling can be time-consuming and labor-intensive, leading to bottlenecks in the production line. With automated sauce filler equipment, you can fill bottles and containers quickly and accurately, increasing productivity and reducing production costs.

In addition to accuracy and efficiency, sauce filler equipment also helps improve the overall quality of the sauce. By using a filler that is specifically designed for sauces, you can minimize air bubbles and ensure a smooth and consistent texture in the final product. This can have a significant impact on the taste and appearance of the sauce, making it more appealing to consumers.

Furthermore, sauce filler equipment can help reduce the risk of contamination in the production process. By automating the filling process, you can minimize the need for manual handling of the sauce, reducing the risk of bacteria or other contaminants entering the product. This can help improve food safety standards and protect the reputation of your brand.

Another advantage of using sauce filler equipment is the versatility it offers. Whether you are filling bottles, jars, pouches, or other types of containers, there is a filler that can meet your specific needs. This flexibility allows you to adapt to changing market demands and production requirements, ensuring that you can continue to meet the needs of your customers.

Overall, sauce filler equipment offers a wide range of benefits for food production facilities that deal with sauces of all kinds. From improved accuracy and efficiency to enhanced quality and safety, investing in the right filler can have a significant impact on your production process. Whether you are a small artisanal producer or a large-scale manufacturer, having the right equipment can help you streamline your operations and deliver high-quality sauces to your customers.