Table of Contents

Benefits of Using Granual Powder Can Packaging Line

Granular powder can packaging lines are an essential component of many industries that deal with granular products such as sugar, salt, coffee, and spices. These packaging lines offer numerous benefits that can streamline the packaging process and improve overall efficiency. In this article, we will explore some of the key advantages of using a granular powder can packaging line.

One of the primary benefits of using a granular powder can packaging line is the increased speed and efficiency it provides. These packaging lines are designed to automate the packaging process, allowing for faster and more consistent packaging of granular products. This can help companies meet high production demands and reduce the need for manual labor, ultimately saving time and money.

In addition to speed and efficiency, granular powder can packaging lines also offer improved accuracy and precision. These machines are equipped with advanced technology that ensures precise measurements and consistent packaging, reducing the risk of errors and product waste. This level of accuracy is crucial for maintaining product quality and meeting customer expectations.

Another key benefit of using a granular powder can packaging line is the flexibility it provides. These packaging lines can be easily adjusted to accommodate different can sizes and packaging requirements, making them suitable for a wide range of products. This flexibility allows companies to adapt to changing market demands and expand their product offerings without the need for significant investments in new equipment.

Furthermore, granular powder can packaging lines are designed to enhance product safety and hygiene. These machines are constructed from high-quality materials that are easy to clean and maintain, reducing the risk of contamination and ensuring product integrity. This is particularly important for industries that deal with food products, where maintaining strict hygiene standards is essential.

Additionally, granular powder can packaging lines can help companies reduce their environmental impact. These machines are designed to minimize product waste and optimize packaging materials, leading to a more sustainable packaging process. By reducing waste and using eco-friendly materials, companies can improve their environmental footprint and appeal to environmentally conscious consumers.

Overall, the benefits of using a granular powder can packaging line are numerous and significant. From increased speed and efficiency to improved accuracy and flexibility, these machines offer a range of advantages that can help companies streamline their packaging process and enhance product quality. By investing in a granular powder can packaging line, companies can improve their overall efficiency, reduce costs, and stay competitive in today’s fast-paced market.

Tips for Optimizing Efficiency in Granual Powder Can Packaging Line

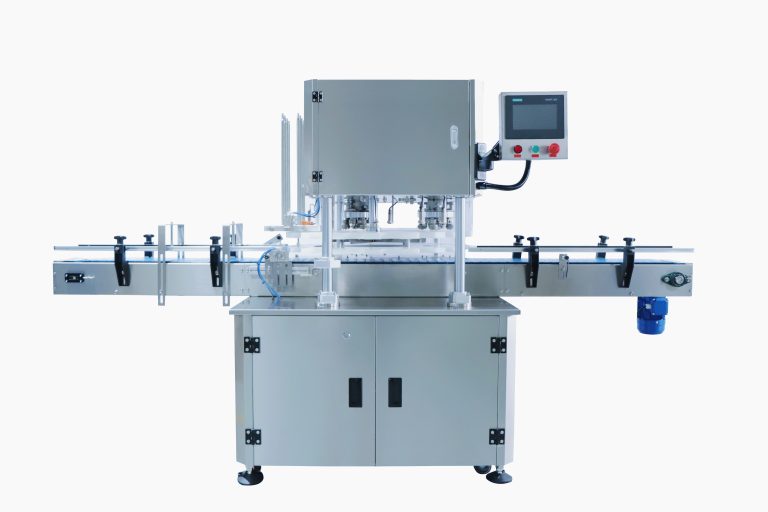

Granular powder can packaging lines are essential for efficiently packaging granular products such as sugar, salt, coffee, and spices. These packaging lines are designed to automate the process of filling, sealing, and labeling cans with granular powder products. To ensure optimal efficiency in a granular powder can packaging line, there are several tips that can be followed.

First and foremost, it is important to properly calibrate the equipment in the packaging line. This includes the filling machine, sealing machine, and labeling machine. Each machine should be set to the correct specifications to ensure accurate and consistent packaging of the granular powder products. Regular maintenance and calibration of the equipment are essential to prevent downtime and ensure smooth operation of the packaging line.

In addition to calibrating the equipment, it is important to properly train the operators who will be working on the packaging line. Operators should be trained on how to operate the equipment, troubleshoot common issues, and perform routine maintenance tasks. Proper training can help prevent errors and ensure that the packaging line runs efficiently.

Another tip for optimizing efficiency in a granular powder can packaging line is to streamline the packaging process. This can be done by organizing the workflow, minimizing unnecessary steps, and eliminating bottlenecks in the packaging line. By streamlining the process, you can increase productivity and reduce the time it takes to package granular powder products.

Furthermore, it is important to use high-quality packaging materials in the packaging line. This includes cans, lids, labels, and any other packaging materials used in the process. Using high-quality materials can help prevent leaks, spills, and other issues that can slow down the packaging process. It is also important to regularly inspect the packaging materials for any defects or damage that could affect the quality of the final product.

Additionally, implementing automation in the packaging line can help improve efficiency. Automated systems can help reduce manual labor, increase speed, and improve accuracy in the packaging process. Automation can also help reduce the risk of human error and ensure consistent packaging of granular powder products.

Lastly, it is important to monitor and analyze the performance of the packaging line regularly. This includes tracking key performance indicators such as production output, downtime, and error rates. By monitoring these metrics, you can identify areas for improvement and make adjustments to optimize efficiency in the packaging line.

In conclusion, optimizing efficiency in a granular powder can packaging line requires proper calibration of equipment, training of operators, streamlining the packaging process, using high-quality packaging materials, implementing automation, and monitoring performance. By following these tips, you can ensure that your packaging line runs smoothly and efficiently, resulting in high-quality packaged granular powder products.