Benefits of Using an Automatic Dual Head Vacuum Capping Machine for Lug Caps

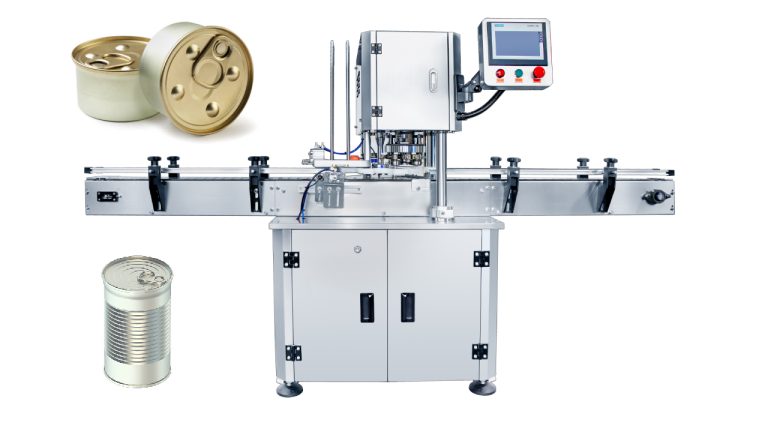

Automatic dual head vacuum capping machines have revolutionized the packaging industry by providing a fast and efficient way to seal containers with lug caps. Lug caps are commonly used in the food and beverage industry to preserve the freshness and quality of products. These caps are known for their secure closure and tamper-evident features, making them a popular choice for manufacturers looking to maintain product integrity.

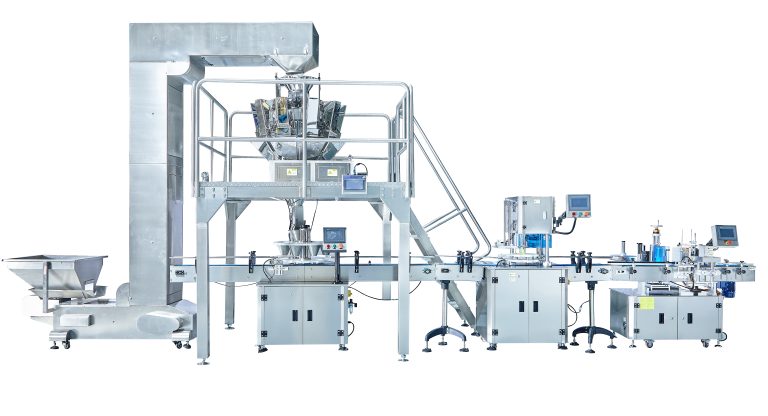

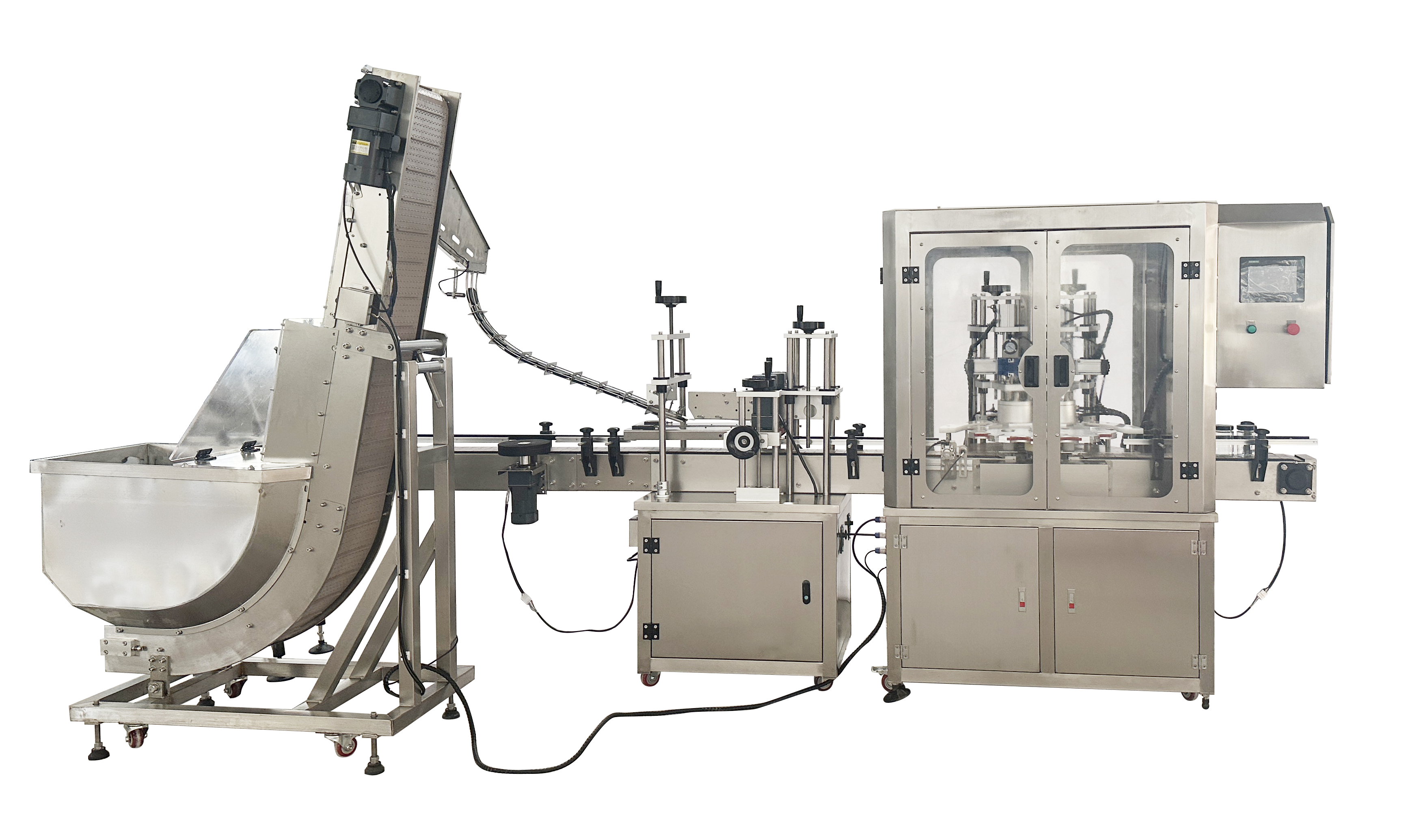

One of the key benefits of using an automatic dual head vacuum capping machine for lug caps is its ability to streamline the packaging process. With two capping heads, this machine can cap two containers simultaneously, doubling the production output and reducing the time required to seal each container. This increased efficiency not only saves time but also labor costs, as fewer operators are needed to operate the machine.

In addition to its speed and efficiency, an automatic dual head vacuum capping machine ensures consistent and reliable sealing of lug caps. The vacuum capping technology creates a tight seal by removing air from the container before applying the cap, preventing oxygen from entering and preserving the product’s freshness. This airtight seal also helps to extend the shelf life of the product, reducing the risk of spoilage and waste.

Furthermore, the dual head design of the machine allows for greater flexibility in packaging operations. Manufacturers can use one capping head for a specific product while using the other head for a different product, enabling them to switch between products quickly and easily. This versatility is especially beneficial for companies that produce a variety of products with different packaging requirements.

Another advantage of using an automatic dual head vacuum capping machine is its user-friendly interface and programmable settings. Operators can easily adjust the capping speed, torque, and vacuum level to meet the specific needs of each product. This customization ensures that each container is sealed correctly, preventing leaks and ensuring product quality.

Moreover, automatic dual head vacuum capping machines are designed with safety features to protect operators and prevent accidents. The machines are equipped with sensors that detect any abnormalities during the capping process, such as a misaligned cap or a jammed container. In such cases, the machine will automatically stop to prevent damage to the equipment and ensure the safety of the operators.

In conclusion, the benefits of using an automatic dual head vacuum capping machine for lug caps are numerous. From increased efficiency and productivity to consistent sealing and product quality, this machine offers a cost-effective solution for manufacturers looking to improve their packaging operations. With its user-friendly interface, programmable settings, and safety features, this machine is a valuable asset for any company looking to streamline their packaging process and deliver high-quality products to consumers.