Table of Contents

Benefits of Using a Canned Nuts Quantitative Weighing Filling Machine

Canned nuts are a popular snack enjoyed by many people around the world. Whether you prefer almonds, cashews, or peanuts, having a reliable and efficient way to package these tasty treats is essential for businesses in the food industry. One of the best ways to streamline the packaging process is by using a canned nuts quantitative weighing filling machine.

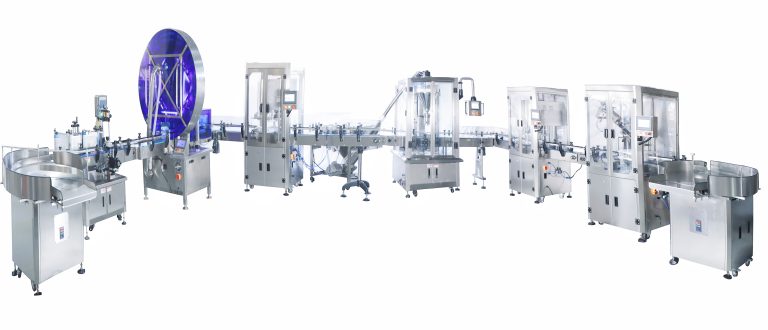

These machines are designed to accurately measure and fill cans with a specific weight of nuts, ensuring consistency and precision in every package. By automating this process, businesses can save time and labor costs while also improving the overall quality of their products.

One of the key benefits of using a canned nuts quantitative weighing filling machine is the increased efficiency it provides. These machines are capable of filling hundreds of cans per hour, far surpassing what could be achieved manually. This means that businesses can increase their production output without sacrificing quality or consistency.

In addition to efficiency, these machines also offer improved accuracy in the filling process. By using advanced weighing technology, the machine can ensure that each can is filled with the exact weight of nuts specified by the operator. This eliminates the risk of underfilling or overfilling, which can lead to customer complaints or even regulatory issues.

Another advantage of using a canned nuts quantitative weighing filling machine is the reduction of product waste. By accurately measuring and filling each can, businesses can minimize the amount of nuts that are wasted during the packaging process. This not only saves money but also helps to reduce the environmental impact of production.

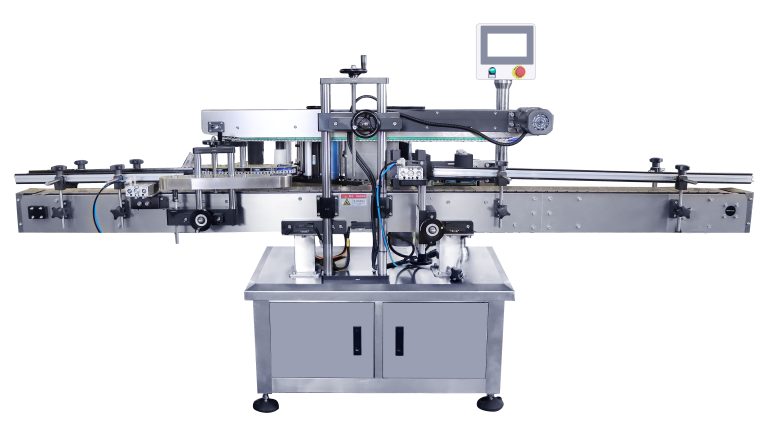

Furthermore, these machines are easy to operate and maintain, making them a valuable investment for businesses of all sizes. With user-friendly interfaces and simple controls, operators can quickly learn how to use the machine effectively. Additionally, regular maintenance and cleaning are straightforward, ensuring that the machine remains in optimal working condition for years to come.

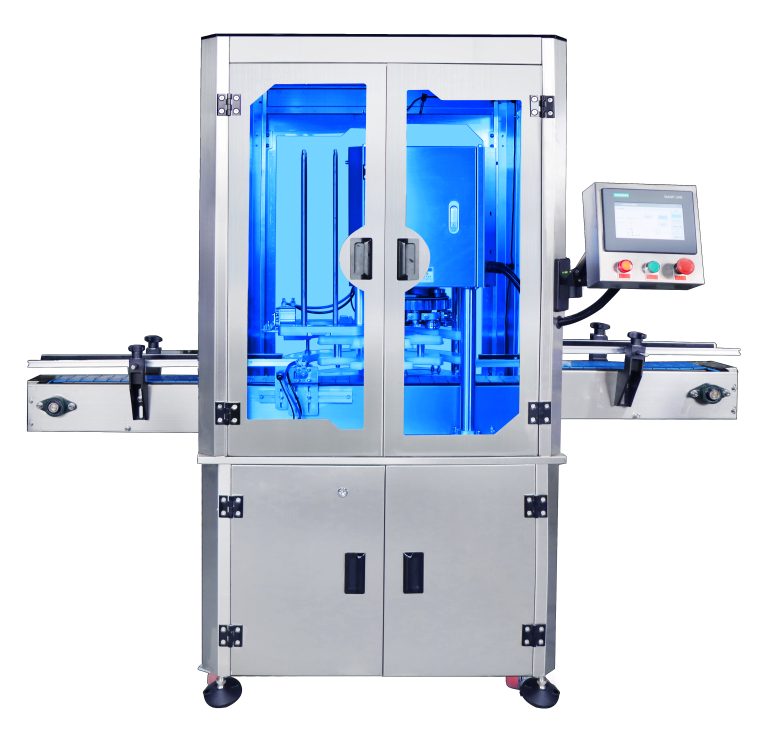

By investing in a canned nuts quantitative weighing filling machine, businesses can also improve the overall safety of their operations. These machines are equipped with safety features such as emergency stop buttons and protective guards to prevent accidents and injuries. This not only protects employees but also helps to maintain a positive work environment.

Overall, the benefits of using a canned nuts quantitative weighing filling machine are clear. From increased efficiency and accuracy to reduced waste and improved safety, these machines offer a wide range of advantages for businesses in the food industry. By investing in this technology, companies can streamline their packaging process, enhance product quality, and ultimately increase their bottom line.

How to Choose the Right Canned Nuts Quantitative Weighing Filling Machine for Your Business

When it comes to packaging nuts in cans, having the right filling machine is crucial for ensuring accuracy and efficiency in your production process. A canned nuts quantitative weighing filling machine is specifically designed to accurately measure and fill cans with a predetermined weight of nuts. This not only helps in maintaining consistency in the product but also saves time and labor costs in the long run.

There are several factors to consider when choosing the right canned nuts quantitative weighing filling machine for your business. One of the most important factors is the capacity of the machine. Depending on the volume of nuts you need to package, you will need to choose a machine that can handle the required output. It is essential to consider both the speed and accuracy of the machine to ensure that it can meet your production needs.

Another important factor to consider is the type of nuts you will be packaging. Different types of nuts have varying densities and sizes, which can affect the accuracy of the filling machine. It is important to choose a machine that is specifically designed to handle the type of nuts you will be packaging to ensure accurate and consistent results.

In addition to capacity and type of nuts, it is also important to consider the level of automation of the filling machine. Fully automated machines can significantly increase efficiency and reduce labor costs, but they may also require a higher initial investment. Semi-automated machines, on the other hand, offer a good balance between efficiency and cost. It is important to weigh the pros and cons of each option based on your specific business needs.

When choosing a canned nuts quantitative weighing filling machine, it is also important to consider the ease of use and maintenance of the machine. A user-friendly machine can help reduce training time and minimize errors in operation. Additionally, a machine that is easy to maintain can help prevent downtime and ensure consistent performance.

It is also important to consider the overall quality and reliability of the filling machine. Investing in a high-quality machine from a reputable manufacturer can help ensure that the machine will perform consistently and reliably over time. It is important to do thorough research and read reviews from other users to ensure that you are choosing a machine that meets your quality standards.

In conclusion, choosing the right canned nuts quantitative weighing filling machine for your business is a crucial decision that can have a significant impact on your production process. By considering factors such as capacity, type of nuts, level of automation, ease of use and maintenance, and overall quality and reliability, you can make an informed decision that will help streamline your production process and improve efficiency in packaging nuts in cans.