Table of Contents

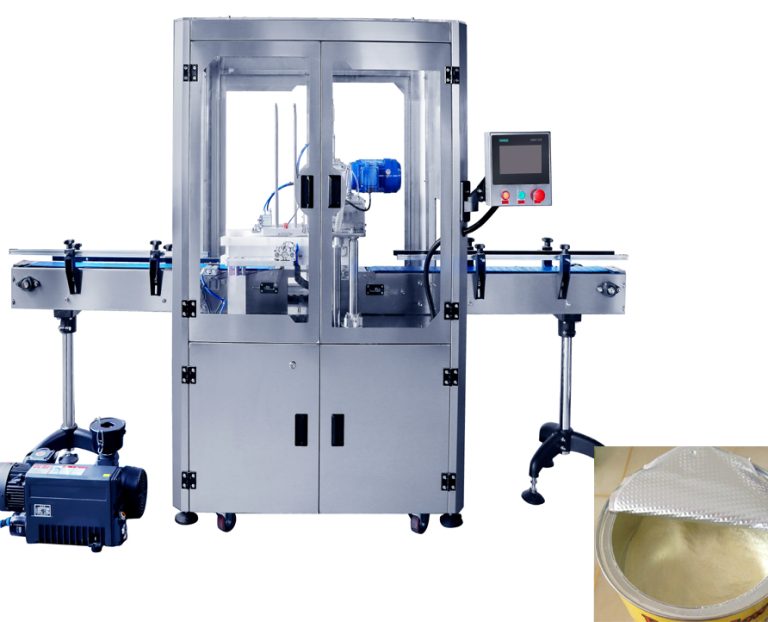

อุปกรณ์สกรูฝาเกลียวซอสพริกมีบทบาทสำคัญในอุตสาหกรรมการผลิตอาหาร โดยเฉพาะอย่างยิ่งในการผลิตผลิตภัณฑ์ซอสพริก อุปกรณ์เฉพาะทางนี้ได้รับการออกแบบมาให้ติดฝาดึงบนขวดซอสพริกได้อย่างมีประสิทธิภาพและแม่นยำ ช่วยให้มั่นใจได้ถึงการปิดผนึกที่ปลอดภัยและรักษาความสดของผลิตภัณฑ์ การใช้อุปกรณ์สกรูฝาจุกซอสพริกในการผลิตอาหารมีประโยชน์หลายประการ ซึ่งเราจะกล่าวถึงในบทความนี้

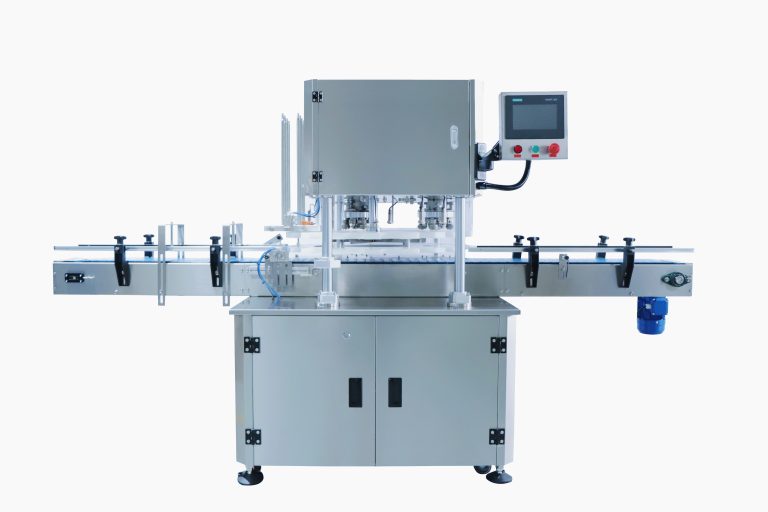

ข้อดีหลักอย่างหนึ่งของการใช้อุปกรณ์สกรูฝาจุกซอสพริกคือความสามารถในการปรับปรุงกระบวนการผลิต การทำให้กระบวนการสมัครฝาเป็นแบบอัตโนมัติ ผู้ผลิตสามารถเพิ่มผลผลิตได้อย่างมากและลดต้นทุนค่าแรง อุปกรณ์นี้ได้รับการออกแบบมาให้ทำงานได้อย่างรวดเร็วและมีประสิทธิภาพ ช่วยให้ปิดฝาขวดปริมาณมากได้ในระยะเวลาอันสั้น สิ่งนี้ไม่เพียงปรับปรุงประสิทธิภาพโดยรวม แต่ยังช่วยตอบสนองความต้องการของสภาพแวดล้อมการผลิตที่รวดเร็ว

นอกเหนือจากการปรับปรุงประสิทธิภาพแล้ว อุปกรณ์สกรูฝาเกลียวซอสพริกยังช่วยรับประกันคุณภาพและความสม่ำเสมอของผลิตภัณฑ์ขั้นสุดท้ายอีกด้วย การใช้ฝาปิดด้วยมืออาจเสี่ยงต่อข้อผิดพลาดของมนุษย์ ส่งผลให้ขวดปิดผนึกไม่ถูกต้อง ซึ่งอาจส่งผลต่อความสดและความปลอดภัยของซอสพริก ด้วยอุปกรณ์อัตโนมัติ ผู้ผลิตสามารถปิดผนึกขวดทุกขวดได้อย่างแม่นยำและสม่ำเสมอ ซึ่งช่วยลดความเสี่ยงของการรั่วไหลหรือการปนเปื้อน ความสม่ำเสมอในระดับนี้เป็นสิ่งจำเป็นสำหรับการรักษาคุณภาพและชื่อเสียงของผลิตภัณฑ์

นอกจากนี้ อุปกรณ์สกรูฝาจุกซอสพริกยังได้รับการออกแบบมาให้ใช้งานได้หลากหลายและปรับให้เข้ากับขนาดและรูปร่างของขวดที่แตกต่างกันได้ ความยืดหยุ่นนี้ทำให้ผู้ผลิตสามารถสลับระหว่างการดำเนินการผลิตได้อย่างง่ายดาย โดยไม่ต้องปรับแต่งหรือปรับแต่งเพิ่มเติม ไม่ว่าจะผลิตซอสพริกขวดเล็กหรือขวดใหญ่ อุปกรณ์นี้สามารถรองรับความต้องการด้านบรรจุภัณฑ์ได้หลากหลาย ทำให้เป็นทรัพย์สินที่มีค่าสำหรับโรงงานผลิตอาหารที่มีสายผลิตภัณฑ์ที่หลากหลาย

ประโยชน์หลักอีกประการหนึ่งของการใช้อุปกรณ์สกรูฝาจุกซอสพริกคือ ความทนทานและความน่าเชื่อถือ เครื่องจักรเหล่านี้สร้างขึ้นเพื่อให้ทนทานต่อการใช้งานต่อเนื่องอันเข้มงวดในสภาพแวดล้อมการผลิต ทำให้มั่นใจได้ถึงประสิทธิภาพในระยะยาวและการหยุดทำงานน้อยที่สุด ด้วยการบำรุงรักษาอย่างสม่ำเสมอและการดูแลรักษาอย่างเหมาะสม อุปกรณ์นี้สามารถให้บริการที่เชื่อถือได้นานหลายปี ทำให้เป็นการลงทุนที่คุ้มค่าสำหรับผู้ผลิตที่ต้องการปรับปรุงกระบวนการผลิตของตน

โดยสรุป อุปกรณ์สกรูฝาเกลียวซอสพริกให้ประโยชน์มากมายสำหรับอาหาร สิ่งอำนวยความสะดวกการผลิต ตั้งแต่ประสิทธิภาพที่เพิ่มขึ้นและความสม่ำเสมอไปจนถึงความคล่องตัวและความน่าเชื่อถือ การทำให้กระบวนการติดฝาเป็นแบบอัตโนมัติ ผู้ผลิตสามารถปรับปรุงการดำเนินงานการผลิต ปรับปรุงคุณภาพผลิตภัณฑ์ และตอบสนองความต้องการของตลาดที่มีการแข่งขันสูง เมื่อคำนึงถึงข้อดีเหล่านี้ จึงเห็นได้ชัดว่าอุปกรณ์สกรูฝาจุกซอสพริกเป็นเครื่องมือสำคัญสำหรับโรงงานผลิตอาหารที่ต้องการปรับปรุงกระบวนการผลิตและส่งมอบผลิตภัณฑ์คุณภาพสูงให้กับผู้บริโภค

วิธีเลือกอุปกรณ์สกรูฝาเกลียวซอสพริกที่เหมาะกับธุรกิจของคุณ

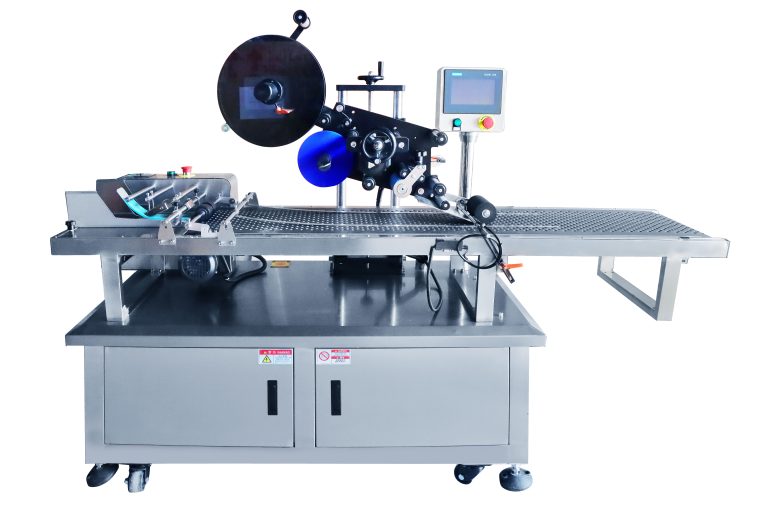

อุปกรณ์สกรูฝาเกลียวซอสพริกเป็นเครื่องมือสำคัญสำหรับธุรกิจในอุตสาหกรรมอาหารที่ผลิตและบรรจุซอสพริก การเลือกอุปกรณ์ที่เหมาะสมสำหรับธุรกิจของคุณเป็นสิ่งสำคัญในการรับรองประสิทธิภาพ ผลผลิต และคุณภาพในกระบวนการผลิตของคุณ มีหลายปัจจัยที่ควรพิจารณาเมื่อเลือกอุปกรณ์สกรูฝาจุกซอสพริก รวมถึงประเภทของฝาปิดที่คุณจะใช้ ขนาดและความเร็วของสายการผลิต และงบประมาณของคุณ

สิ่งแรกๆ ที่ต้องพิจารณาเมื่อเลือกอุปกรณ์สกรูฝาเกลียวซอสพริกคือประเภทของฝาที่คุณจะใช้ ฝาปิดประเภทต่างๆ ต้องใช้อุปกรณ์ที่แตกต่างกันจึงจะใช้งานได้อย่างเหมาะสม ตัวอย่างเช่น ฝาจุกมักใช้กับขวดแก้วซอสพริก และต้องใช้อุปกรณ์เฉพาะในการขันเกลียวเข้ากับขวดให้แน่น ตรวจสอบให้แน่ใจว่าได้เลือกอุปกรณ์ที่เข้ากันได้กับประเภทของฝาปิดที่คุณจะใช้เพื่อหลีกเลี่ยงปัญหาใดๆ ในระหว่างกระบวนการผลิต

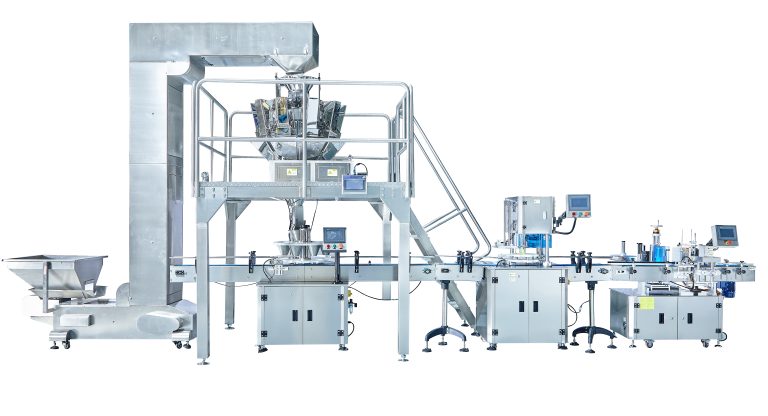

ปัจจัยสำคัญอีกประการหนึ่งที่ต้องพิจารณาคือขนาดและความเร็วของสายการผลิตของคุณ ขนาดของสายการผลิตของคุณจะเป็นตัวกำหนดกำลังการผลิตและขนาดของอุปกรณ์ที่คุณต้องการ หากคุณมีสายการผลิตขนาดเล็ก คุณอาจต้องใช้อุปกรณ์สกรูฝาจุกซอสพริกแบบแมนนวลหรือกึ่งอัตโนมัติเท่านั้น อย่างไรก็ตาม หากคุณมีสายการผลิตขนาดใหญ่ที่มีผลผลิตสูง คุณอาจต้องใช้เครื่องจักรอัตโนมัติเต็มรูปแบบที่สามารถรองรับปริมาณขวดต่อชั่วโมงที่สูงขึ้นได้ พิจารณาความเร็วที่คุณต้องใช้ในการปิดฝาและเลือกอุปกรณ์ที่สามารถตอบสนองความต้องการของสายการผลิตของคุณ

นอกจากนี้ การพิจารณางบประมาณของคุณยังเป็นสิ่งสำคัญเมื่อเลือกอุปกรณ์สกรูฝาเกลียวซอสพริก ราคาของอุปกรณ์อาจแตกต่างกันไปขึ้นอยู่กับยี่ห้อ ขนาด และคุณสมบัติของเครื่อง สิ่งสำคัญคือต้องหาสมดุลระหว่างคุณภาพและความสามารถในการจ่ายเพื่อให้แน่ใจว่าคุณจะได้รับความคุ้มค่ากับเงินที่เสียไปมากที่สุด พิจารณาถึงผลประโยชน์ระยะยาวของการลงทุนในอุปกรณ์คุณภาพสูงซึ่งจะคงอยู่ต่อไปอีกหลายปี และช่วยปรับปรุงประสิทธิภาพของกระบวนการผลิตของคุณ

เมื่อเลือกอุปกรณ์สกรูฝาเกลียวซอสพริกสำหรับธุรกิจของคุณ จำเป็นต้องดำเนินการอย่างละเอียดถี่ถ้วน ค้นคว้าและเปรียบเทียบตัวเลือกต่างๆ เพื่อค้นหาตัวเลือกที่เหมาะสมที่สุดสำหรับความต้องการของคุณ มองหาผู้ผลิตที่มีชื่อเสียงซึ่งนำเสนออุปกรณ์ที่เชื่อถือได้พร้อมคำวิจารณ์ที่ดีจากลูกค้า ลองติดต่อผู้เชี่ยวชาญในอุตสาหกรรมหรือซัพพลายเออร์เพื่อขอคำแนะนำและคำแนะนำในการเลือกอุปกรณ์ที่เหมาะสมสำหรับธุรกิจของคุณ

โดยสรุป การเลือกอุปกรณ์สกรูฝาเกลียวซอสพริกที่ถูกต้องเป็นสิ่งสำคัญสำหรับธุรกิจในอุตสาหกรรมอาหารที่ผลิตและบรรจุซอสพริก พิจารณาปัจจัยต่างๆ เช่น ประเภทของฝาปิดที่คุณจะใช้ ขนาดและความเร็วของสายการผลิต และงบประมาณของคุณในการเลือกอุปกรณ์ ด้วยการสละเวลาในการวิจัยและเปรียบเทียบตัวเลือกต่างๆ คุณจะพบอุปกรณ์ที่ดีที่สุดที่จะช่วยปรับปรุงประสิทธิภาพและคุณภาพของกระบวนการผลิตของคุณ

One of the first things to consider when choosing chili sauce lug cap screw equipment is the type of caps you will be using. Different types of caps require different equipment to apply them properly. For example, lug caps are commonly used for glass jars of chili sauce and require specific equipment to screw them onto the jars securely. Make sure to choose equipment that is compatible with the type of caps you will be using to avoid any issues during the production process.

Another important factor to consider is the size and speed of your production line. The size of your production line will determine the capacity and size of the equipment you will need. If you have a small production line, you may only need a manual or semi-automatic chili sauce lug cap screw equipment. However, if you have a large production line with high output, you may need a fully automatic machine that can handle a higher volume of jars per hour. Consider the speed at which you need to apply the caps and choose equipment that can keep up with the demands of your production line.

Additionally, it is essential to consider your budget when choosing chili sauce lug cap screw equipment. The cost of equipment can vary depending on the brand, size, and features of the machine. It is important to find a balance between quality and affordability to ensure that you are getting the best value for your money. Consider the long-term benefits of investing in high-quality equipment that will last for years to come and help improve the efficiency of your production process.

When selecting chili sauce lug cap screw equipment for your business, it is essential to do thorough research and compare different options to find the best fit for your needs. Look for reputable manufacturers that offer reliable equipment with good customer reviews. Consider reaching out to industry experts or suppliers for recommendations and advice on choosing the right equipment for your business.

In conclusion, choosing the right chili sauce lug cap screw equipment is crucial for businesses in the food industry that produce and package chili sauce. Consider factors such as the type of caps you will be using, the size and speed of your production line, and your budget when selecting equipment. By taking the time to research and compare different options, you can find the best equipment that will help improve the efficiency and quality of your production process.