In the fast-paced world of manufacturing, downtime can be a major setback, especially in mixed production lines. But now, self-adjusting dual-head sealers are here to change the game and eliminate those frustrating pauses.

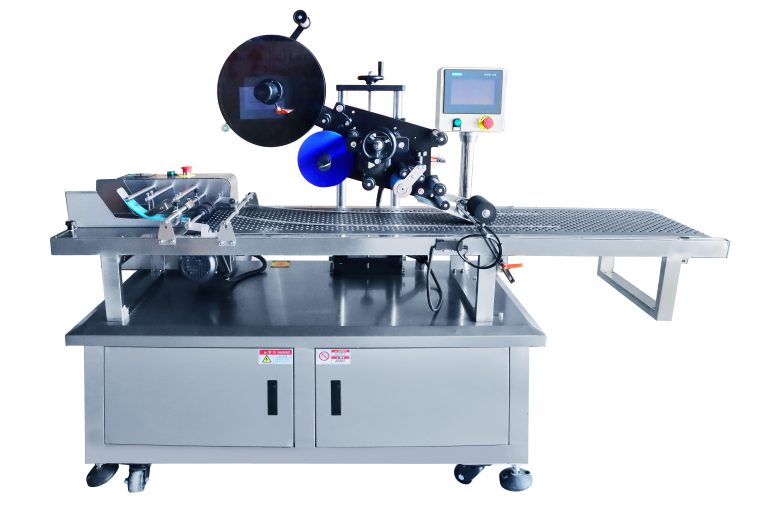

These innovative sealers are designed to adapt seamlessly to the constant changes and variations in a mixed production environment.

Their self-adjusting feature ensures that they can quickly and accurately handle different products and packaging requirements without the need for time-consuming manual adjustments.

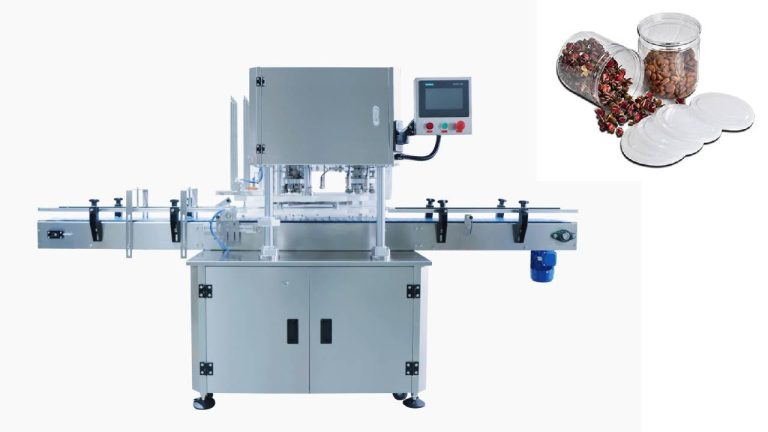

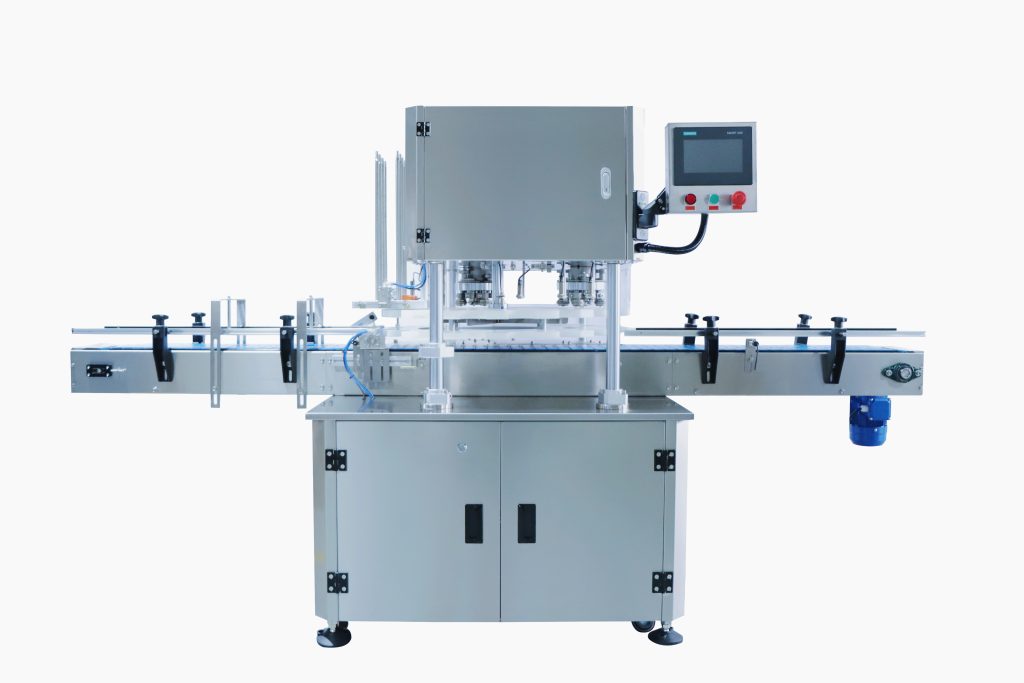

The dual-head configuration significantly boosts productivity. While one head is sealing, the other is getting ready for the next item, minimizing idle time and maximizing output.

With the ability to automatically adjust parameters such as pressure, temperature, and speed, these sealers guarantee consistent and high-quality seals regardless of the product mix. This not only reduces rejects but also enhances the overall efficiency and reliability of the production line.

The self-adjusting mechanism is powered by advanced sensors and intelligent control systems. These components constantly monitor the production process and make real-time adjustments to keep everything running smoothly.

In a mixed production line where diversity is the norm, self-adjusting dual-head sealers offer a seamless solution. They eliminate the hassle and cost associated with downtime, allowing businesses to operate at full capacity and meet customer demands promptly.

In conclusion, self-adjusting dual-head sealers are a game-changer for mixed production lines, providing a reliable and efficient way to keep operations going without a hitch. Say goodbye to downtime and hello to increased productivity and profitability.