Table of Contents

Increased Efficiency in Production Processes

In the world of manufacturing, efficiency is key. Companies are constantly looking for ways to streamline their production processes and increase output without sacrificing quality. One way that many companies are achieving this is by investing in automatic piston filling machines.

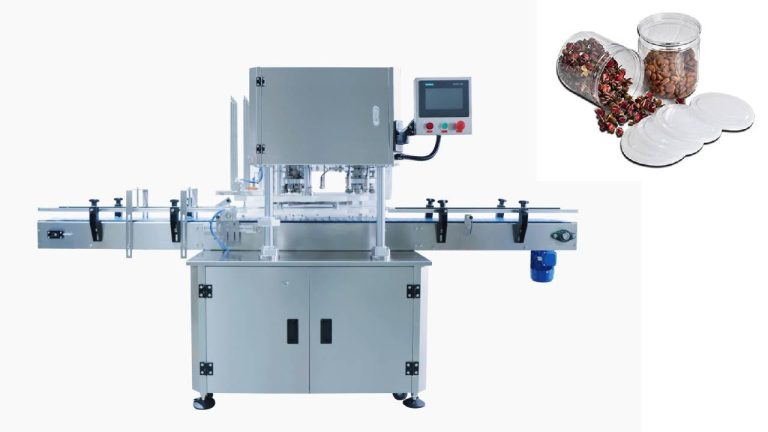

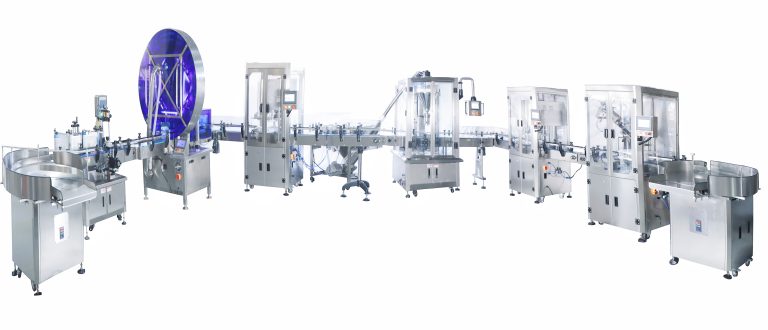

Automatic piston filling machines are a type of packaging equipment that is used to fill containers with liquid products. These machines are designed to be fast, accurate, and reliable, making them an essential tool for companies looking to increase efficiency in their production processes.

One of the main advantages of automatic piston filling machines is their speed. These machines are capable of filling hundreds of containers per minute, far surpassing the output of manual filling methods. This increased speed allows companies to produce more products in less time, ultimately leading to higher profits and a more competitive edge in the market.

In addition to their speed, automatic piston filling machines are also incredibly accurate. These machines are equipped with advanced technology that ensures precise measurements of the liquid being dispensed into each container. This level of accuracy helps to reduce waste and ensure that each product meets the company’s quality standards.

Another advantage of automatic piston filling machines is their reliability. These machines are built to last, with durable components that can withstand the rigors of continuous use. This reliability means that companies can depend on their automatic piston filling machines to perform consistently day in and day out, without the need for frequent maintenance or repairs.

Furthermore, automatic piston filling machines are versatile and can be used to fill a wide range of container sizes and shapes. This flexibility allows companies to use the same machine for multiple products, saving time and money on equipment costs.

Overall, the advantages of automatic piston filling machines are clear. These machines offer increased speed, accuracy, reliability, and versatility, making them an essential tool for companies looking to improve efficiency in their production processes. By investing in automatic piston filling machines, companies can increase output, reduce waste, and ultimately boost their bottom line.

Improved Accuracy and Consistency in Filling Operations

In the manufacturing industry, precision and consistency are key factors in ensuring the quality of products. This is especially true in the food and beverage, pharmaceutical, and cosmetic industries where accurate filling of containers is crucial. One technology that has revolutionized the filling process is the automatic piston filling machine. This advanced equipment offers a range of advantages over traditional filling methods, including improved accuracy and consistency in filling operations.

One of the primary benefits of using an automatic piston filling machine is its ability to precisely control the amount of product dispensed into each container. Unlike manual filling methods, which rely on human operators to gauge the correct amount of product to dispense, automatic piston filling machines use advanced technology to accurately measure and dispense the desired volume of product. This ensures that each container is filled with the exact amount of product, eliminating the risk of underfilling or overfilling.

Furthermore, automatic piston filling machines offer a high level of consistency in filling operations. By using a piston mechanism to dispense product, these machines can maintain a consistent fill level across all containers, regardless of variations in viscosity or density of the product. This results in a uniform product presentation and helps to maintain the brand’s reputation for quality and consistency.

Another advantage of automatic piston filling machines is their versatility. These machines can be easily adjusted to accommodate a wide range of container sizes and shapes, making them suitable for a variety of products. Whether filling bottles, jars, tubes, or pouches, automatic piston filling machines can be customized to meet the specific requirements of each product line. This flexibility allows manufacturers to streamline their production processes and reduce downtime associated with changing over to different container sizes.

In addition to improved accuracy and consistency, automatic piston filling machines offer increased efficiency in filling operations. These machines are capable of filling a large number of containers in a short amount of time, significantly reducing the time and labor required for manual filling. This not only increases productivity but also reduces the risk of human error, resulting in higher quality products and lower production costs.

Furthermore, automatic piston filling machines are easy to operate and maintain, requiring minimal training for operators. With user-friendly controls and automated features, these machines can be quickly set up and adjusted for different products, allowing for seamless integration into existing production lines. Additionally, automatic piston filling machines are designed for easy cleaning and maintenance, ensuring optimal performance and longevity.

Overall, the advantages of automatic piston filling machines make them an essential investment for manufacturers looking to improve the accuracy, consistency, and efficiency of their filling operations. By utilizing advanced technology and automation, these machines offer a cost-effective solution for achieving high-quality products and maintaining a competitive edge in the market. Whether filling food and beverage products, pharmaceuticals, or cosmetics, automatic piston filling machines provide a reliable and versatile solution for manufacturers seeking to optimize their production processes.