Benefits of Using Snack Food Plastic Jar Easy Open Lid Sealing Machine Snack foods are a popular choice for consumers looking for a quick and convenient snack option. From chips to nuts to candies, snack foods come in a variety of packaging options, including plastic jars. One common issue with…

Benefits of Using Automatic Single Head Starch Can Auger Filling Machine The automatic single head starch can auger filling machine is a highly efficient and reliable piece of equipment that offers numerous benefits to businesses in the food processing industry. This machine is specifically designed to accurately fill starch into…

Benefits of Using a Canned Nuts Quantitative Weighing Filling Machine Canned nuts are a popular snack enjoyed by many people around the world. Whether you prefer almonds, cashews, or peanuts, having a reliable and efficient way to package these tasty treats is essential for businesses in the food industry. One…

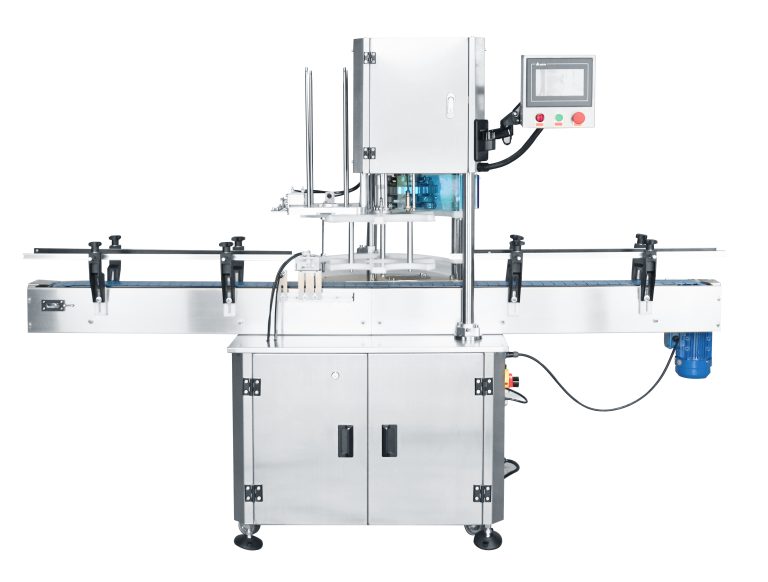

Understanding the Efficiency of Double Head Servo Capping Machines for Bottles and Jars The double head servo capping machine for bottles and jars is a revolutionary piece of equipment that has significantly transformed the packaging industry. This machine, designed with precision and efficiency in mind, has become an indispensable tool…

Benefits of Using Cake Box Tape for Seaming Machines Cake box tape is a specialized adhesive tape that is commonly used in the packaging industry for sealing cake boxes. However, cake box tape can also be utilized in other applications, such as on seaming machines. Seaming machines are used in…

Effective Ways to Seal Plastic Jars for Maximum Freshness Plastic jars are a convenient and versatile storage solution for a variety of items, from food to craft supplies. However, to ensure that the contents remain fresh and protected from outside elements, it is important to properly seal the jars. There…