Automatic single-head servo capping machines have become an indispensable part of modern packaging lines. This comprehensive guide will take you through everything you need to know about them.

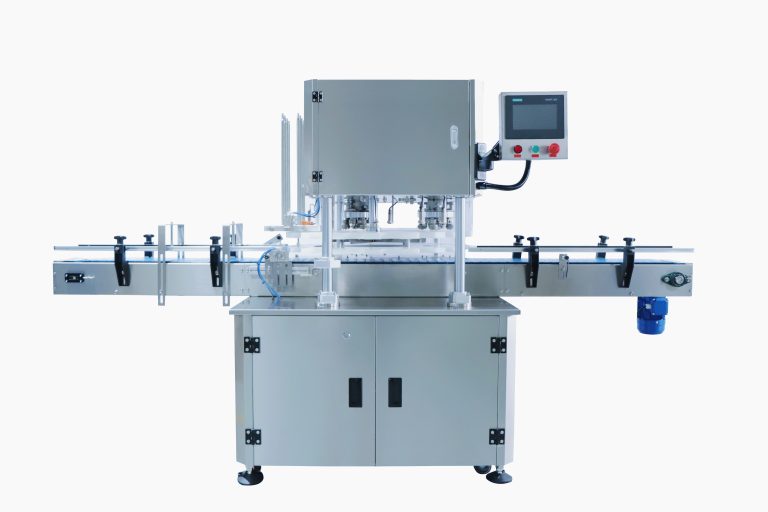

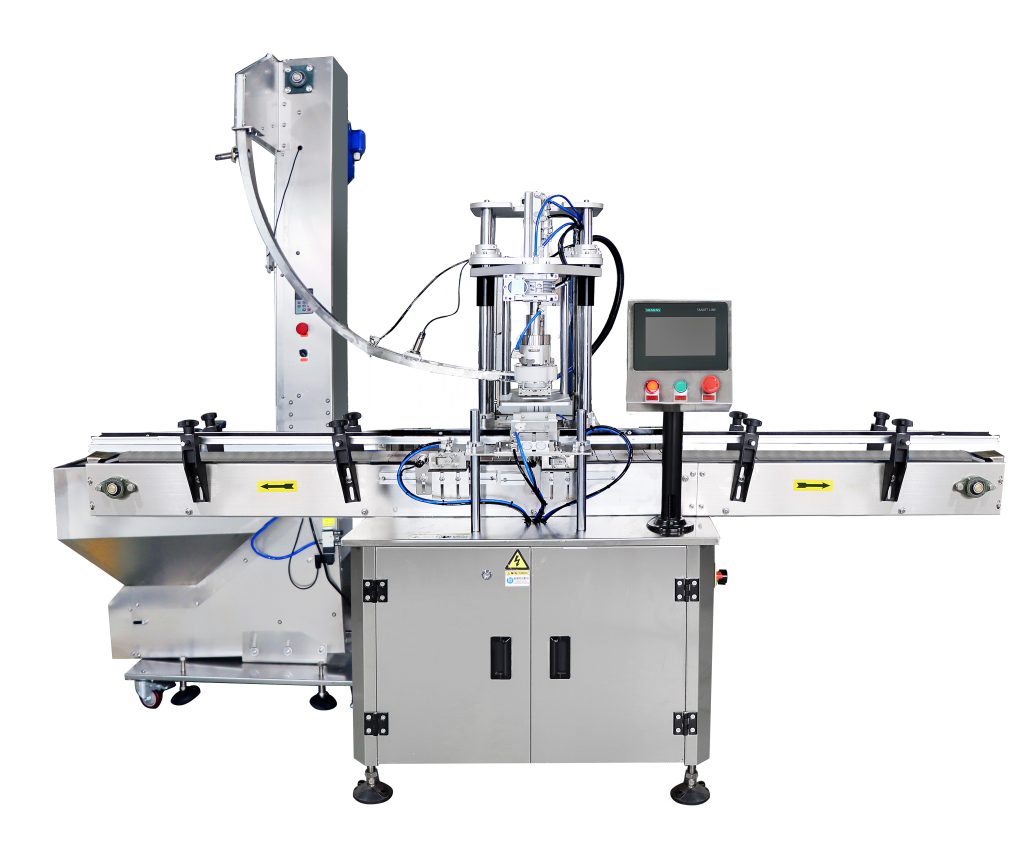

Let’s start with the basics. These machines are designed to cap containers quickly and accurately, with a single capping head for focused and precise operation.

The key component is the servo system, which provides precise control over the capping process. It ensures consistent torque and speed, resulting in tightly sealed caps every time.

One of the significant advantages of these machines is their adaptability. They can handle a wide range of container sizes and cap types, making them suitable for diverse packaging needs.

The speed and efficiency of automatic single-head servo capping machines are impressive. They can significantly increase production output compared to manual or less advanced capping methods.

When it comes to maintenance, they are relatively straightforward. Regular inspections and lubrication of moving parts can keep them running smoothly for a long time.

Installation is another aspect to consider. These machines need to be set up properly to integrate seamlessly with the rest of the packaging line. Professional installation and calibration are often recommended.

In terms of cost, while the initial investment may be higher than traditional capping methods, the long-term benefits in terms of productivity, quality, and reduced labor costs often outweigh the upfront expense.

To ensure optimal performance, it’s essential to source these machines from reliable manufacturers with a proven track record and good after-sales support.

In conclusion, automatic single-head servo capping machines offer a reliable and efficient solution for modern packaging operations.

Understanding their features, benefits, and maintenance requirements can help you make an informed decision for your business.