Table of Contents

Increased Efficiency and Productivity

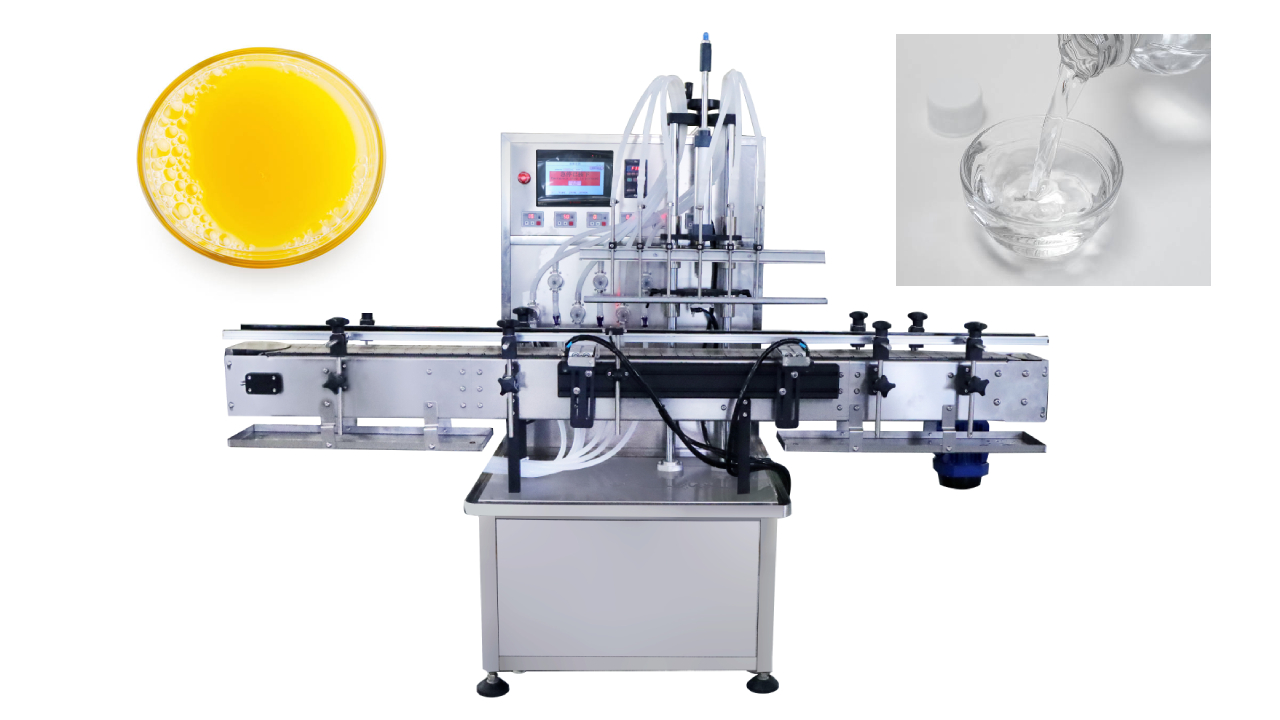

In the manufacturing industry, efficiency and productivity are key factors that can make or break a business. One way to improve these aspects is by investing in the right equipment, such as the automatic magnetic pump liquid filling machine. This innovative technology offers a range of advantages that can help businesses streamline their operations and increase output.

One of the main advantages of the automatic magnetic pump liquid filling machine is its speed and accuracy. Traditional filling methods can be time-consuming and prone to human error, leading to inconsistencies in product quality and output. With an automatic filling machine, the process is automated, ensuring precise measurements and consistent results every time. This not only saves time but also reduces waste and improves overall product quality.

Another advantage of the automatic magnetic pump liquid filling machine is its versatility. These machines can be easily adjusted to accommodate different types of liquids, viscosities, and container sizes. This flexibility allows businesses to quickly switch between products without the need for extensive retooling or downtime. As a result, production can be ramped up or scaled back as needed, making it easier to meet changing market demands.

In addition to speed and versatility, the automatic magnetic pump liquid filling machine also offers improved safety and hygiene. Manual filling methods can expose workers to hazardous chemicals or fumes, increasing the risk of accidents or health issues. By automating the filling process, businesses can minimize human contact with potentially harmful substances, creating a safer work environment for employees. Furthermore, these machines are designed to meet strict hygiene standards, ensuring that products are filled in a clean and sanitary manner.

The automatic magnetic pump liquid filling machine also helps businesses save on labor costs. By automating the filling process, businesses can reduce the need for manual labor, freeing up employees to focus on other tasks. This not only improves efficiency but also allows businesses to reallocate resources to areas that require more attention. Additionally, the consistent and accurate results produced by these machines can help businesses avoid costly mistakes or rework, further reducing operational expenses.

Overall, the automatic magnetic pump liquid filling machine offers a range of advantages that can help businesses improve efficiency and productivity. From speed and accuracy to versatility and safety, these machines are a valuable investment for any manufacturing operation. By automating the filling process, businesses can streamline operations, increase output, and ultimately, boost their bottom line. With the right equipment in place, businesses can stay ahead of the competition and meet the demands of today’s fast-paced market.

Cost Savings and Reduced Waste

In the world of manufacturing and production, efficiency is key. Companies are constantly looking for ways to streamline their processes, reduce waste, and ultimately save money. One way that many companies are achieving these goals is by investing in automatic magnetic pump liquid filling machines. These machines offer a number of advantages over traditional filling methods, including cost savings and reduced waste.

One of the primary advantages of automatic magnetic pump liquid filling machines is their ability to accurately dispense the exact amount of liquid needed for each product. This precision ensures that there is no overfilling or underfilling, which can lead to costly product waste. By eliminating the need for manual filling, these machines also reduce the risk of human error, further increasing efficiency and reducing waste.

In addition to reducing waste, automatic magnetic pump liquid filling machines can also help companies save money by increasing production speeds. These machines are capable of filling containers at a much faster rate than manual methods, allowing companies to produce more products in less time. This increased efficiency not only saves money on labor costs, but also allows companies to meet customer demand more quickly, potentially increasing sales and revenue.

Another cost-saving advantage of automatic magnetic pump liquid filling machines is their ability to adapt to different types of containers and products. These machines can be easily adjusted to accommodate different bottle sizes, shapes, and materials, making them versatile and cost-effective for companies that produce a variety of products. This flexibility eliminates the need for multiple filling machines, saving companies both space and money.

Furthermore, automatic magnetic pump liquid filling machines are designed to be easy to operate and maintain, further reducing costs associated with training and upkeep. These machines are equipped with user-friendly interfaces and can be programmed to fill specific amounts of liquid with the push of a button. Additionally, many models are self-cleaning, reducing the time and resources needed for maintenance.

Overall, the advantages of automatic magnetic pump liquid filling machines in terms of cost savings and reduced waste are clear. These machines offer precision, efficiency, versatility, and ease of use, all of which contribute to a more streamlined and cost-effective production process. By investing in these machines, companies can not only save money on labor and materials, but also increase production speeds, meet customer demand more effectively, and ultimately improve their bottom line.