Benefits of Using a Dustproof Plastic Lid Capping Machine for Powder Can

In the manufacturing industry, efficiency and precision are key factors in ensuring the quality of the final product. When it comes to capping powder cans, using a dustproof plastic lid capping machine can offer numerous benefits that can streamline the production process and improve overall product quality.

One of the primary benefits of using a dustproof plastic lid capping machine is its ability to prevent contamination of the powder inside the can. Dust and other particles can easily infiltrate the can during the capping process, leading to potential quality issues and product recalls. By using a dustproof capping machine, manufacturers can ensure that the powder remains free from contaminants, maintaining its integrity and quality.

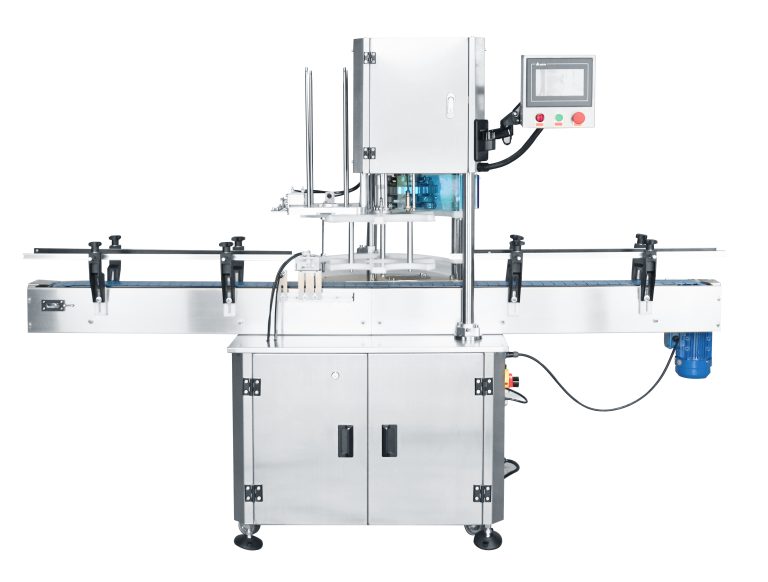

Additionally, a dustproof plastic lid capping machine can help improve the overall efficiency of the production process. Manual capping can be time-consuming and labor-intensive, leading to bottlenecks in the production line. With a capping machine, cans can be capped quickly and accurately, reducing the risk of human error and increasing the overall output of the production line.

Furthermore, a dustproof plastic lid capping machine can also help reduce waste in the manufacturing process. When cans are capped manually, there is a higher risk of spillage and product loss. By using a capping machine, manufacturers can ensure that each can is capped securely and without any spillage, reducing waste and improving overall efficiency.

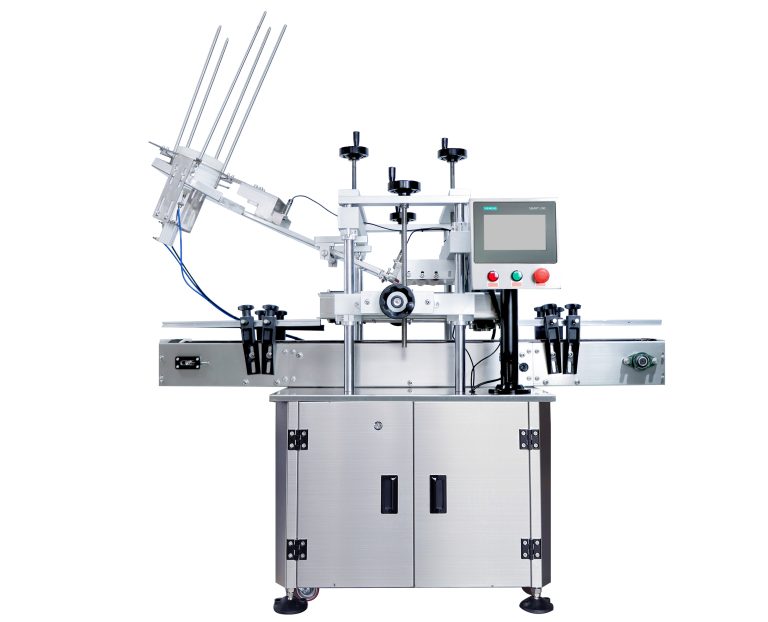

Another benefit of using a dustproof plastic lid capping machine is its versatility. These machines can be easily adjusted to accommodate different can sizes and lid types, making them suitable for a wide range of production needs. Whether manufacturers are capping small or large cans, a dustproof capping machine can provide a reliable and consistent capping solution.

In addition to these benefits, a dustproof plastic lid capping machine can also help improve workplace safety. Manual capping can be a repetitive and physically demanding task, leading to potential injuries and strain on workers. By automating the capping process, manufacturers can reduce the risk of workplace injuries and create a safer working environment for their employees.

Overall, the benefits of using a dustproof plastic lid capping machine for powder cans are clear. From preventing contamination and improving efficiency to reducing waste and enhancing workplace safety, these machines offer a range of advantages that can help manufacturers streamline their production process and deliver high-quality products to their customers.

In conclusion, investing in a dustproof plastic lid capping machine is a smart choice for manufacturers looking to improve the quality and efficiency of their production process. By utilizing these machines, manufacturers can ensure that their powder cans are capped securely and without contamination, leading to higher-quality products and increased customer satisfaction.