Benefits of Using a Fully Automatic Plastic Cover Press Capping Machine for Food Cans

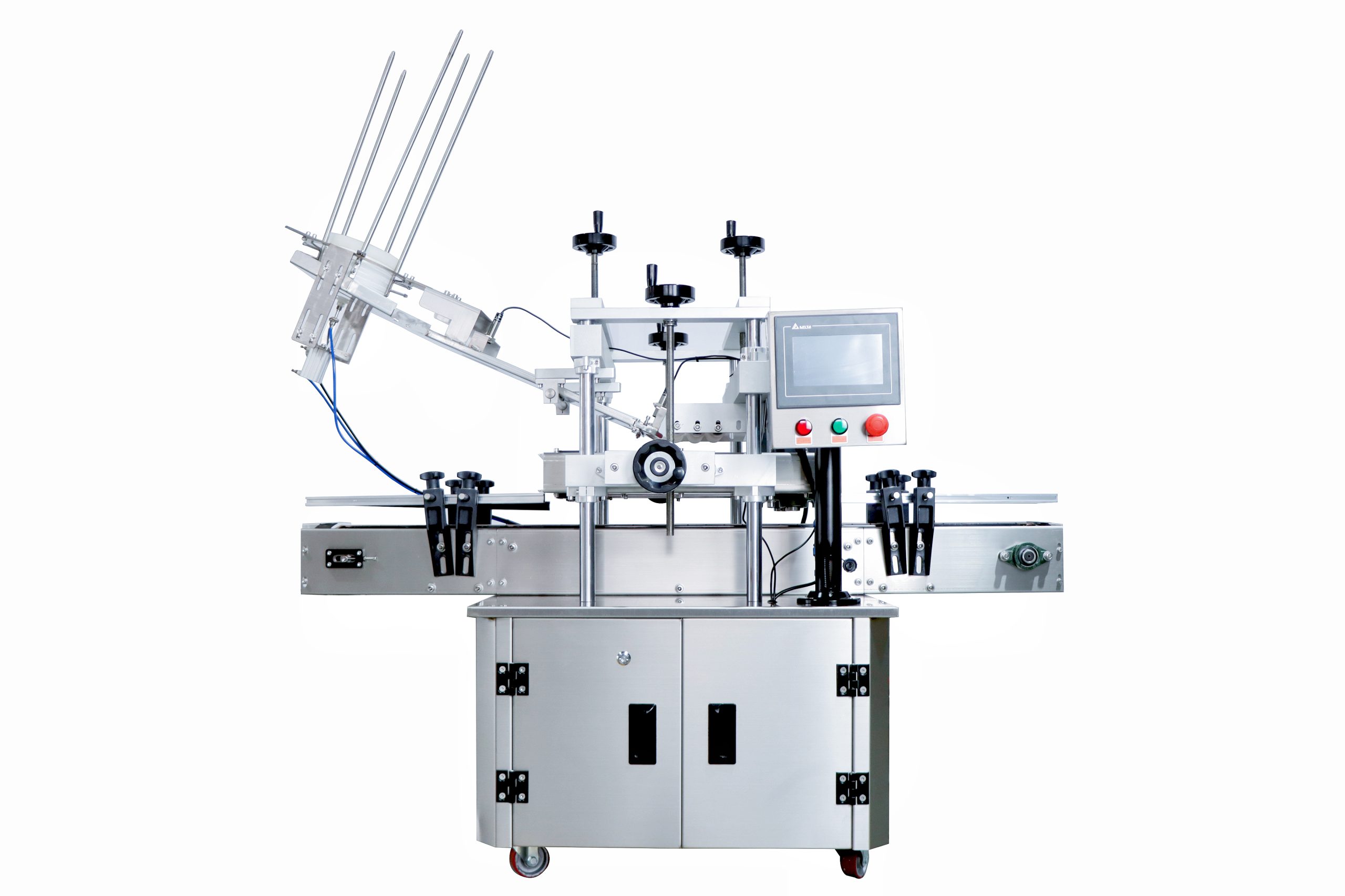

In the food industry, packaging plays a crucial role in ensuring the safety and quality of products. One important aspect of packaging is the sealing of food cans, which helps to prevent contamination and spoilage. Traditionally, manual capping machines have been used to seal food cans, but these machines can be time-consuming and labor-intensive. In recent years, fully automatic plastic cover press capping machines have emerged as a more efficient and cost-effective solution for sealing food cans.

One of the key benefits of using a fully automatic plastic cover press capping machine is its speed and efficiency. These machines are capable of sealing hundreds of food cans per hour, significantly reducing the time and labor required for the capping process. This increased efficiency can help food manufacturers meet production deadlines and improve overall productivity.

Additionally, fully automatic plastic cover press capping machines are designed to provide consistent and reliable sealing results. Manual capping machines rely on the skill and experience of the operator, which can lead to variations in the tightness and quality of the seals. In contrast, automatic capping machines are programmed to apply a consistent amount of pressure to each can, ensuring a uniform and secure seal every time.

Another benefit of using a fully automatic plastic cover press capping machine is its versatility. These machines are capable of sealing a wide range of food can sizes and shapes, making them suitable for use in various food packaging applications. Whether sealing small cans of spices or large cans of fruits and vegetables, automatic capping machines can accommodate different packaging requirements with ease.

Furthermore, fully automatic plastic cover press capping machines are designed to be user-friendly and easy to operate. With intuitive controls and automated processes, these machines require minimal training for operators to use effectively. This can help food manufacturers reduce the risk of human error and ensure consistent sealing results across different production runs.

In addition to their speed, efficiency, consistency, and versatility, fully automatic plastic cover press capping machines also offer cost savings for food manufacturers. By reducing the time and labor required for the capping process, these machines can help companies lower their production costs and improve their bottom line. Additionally, the reliable sealing results provided by automatic capping machines can help to minimize product waste and reduce the risk of product recalls due to faulty seals.

Overall, the benefits of using a fully automatic plastic cover press capping machine for food cans are clear. From increased speed and efficiency to consistent sealing results and cost savings, these machines offer a range of advantages for food manufacturers looking to improve their packaging processes. By investing in an automatic capping machine, companies can enhance the quality and safety of their products while streamlining their production operations.