Table of Contents

Benefits of Using Oat Tin Can Packing Machine Line

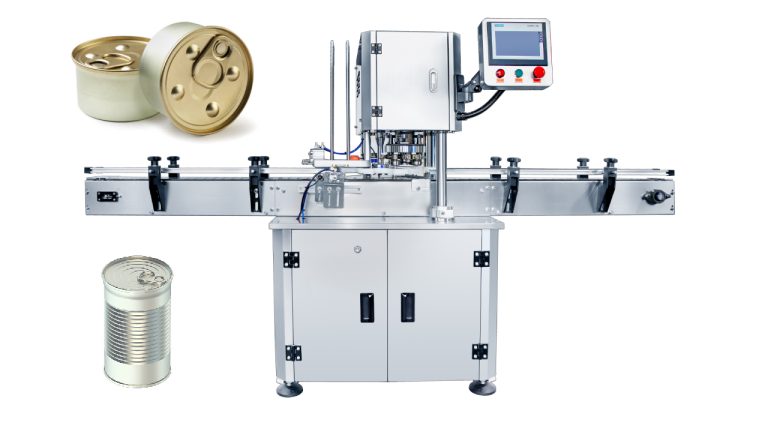

In the food packaging industry, efficiency and accuracy are key factors in ensuring the quality and safety of products. One of the most popular packaging options for food products is tin cans, as they provide a durable and airtight seal that helps to preserve the freshness of the contents. When it comes to packing oat products in tin cans, using a specialized oat tin can packing machine line can offer numerous benefits for manufacturers.

One of the primary benefits of using an oat tin can packing machine line is the increased efficiency it provides. These machines are designed to automate the packing process, reducing the need for manual labor and streamlining production. This not only saves time but also helps to minimize the risk of human error, ensuring that each tin can is filled accurately and consistently. By increasing efficiency, manufacturers can boost their overall productivity and meet the demands of a fast-paced market.

Another advantage of using an oat tin can packing machine line is the improved quality control it offers. These machines are equipped with sensors and monitoring systems that can detect any abnormalities in the packing process, such as underfilled or overfilled cans. This allows manufacturers to quickly identify and address any issues, ensuring that only high-quality products are sent out to consumers. By maintaining strict quality control standards, manufacturers can build trust with their customers and enhance their brand reputation.

In addition to efficiency and quality control, using an oat tin can packing machine line can also help to reduce waste and minimize costs. These machines are designed to optimize the use of materials, ensuring that each tin can is filled with the precise amount of product. This can help to reduce product waste and minimize the need for rework, ultimately saving manufacturers money in the long run. By cutting down on waste and improving efficiency, manufacturers can increase their profitability and remain competitive in the market.

Furthermore, an oat tin can packing machine line can also enhance the safety of the packing process. These machines are equipped with safety features such as emergency stop buttons and protective guards to prevent accidents and injuries. By prioritizing the safety of their workers, manufacturers can create a more positive work environment and reduce the risk of costly workplace incidents. This not only benefits the employees but also helps to protect the reputation of the company.

Overall, the benefits of using an oat tin can packing machine line are clear. From increased efficiency and quality control to reduced waste and improved safety, these machines offer numerous advantages for manufacturers in the food packaging industry. By investing in a specialized packing machine line, manufacturers can enhance their production processes, increase their profitability, and maintain a competitive edge in the market.

How to Choose the Right Oat Tin Can Packing Machine Line for Your Business

When it comes to packaging oat tin cans, having the right packing machine line is essential for ensuring efficiency and quality in your production process. With so many options available on the market, choosing the right oat tin can packing machine line for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting a packing machine line for oat tin cans.

First and foremost, it is important to consider the production capacity of the oat tin can packing machine line. You will need to determine the volume of oat tin cans that you need to pack on a daily basis in order to choose a machine line that can meet your production requirements. It is important to choose a machine line that can handle your current production needs as well as any potential future growth in your business.

Another important factor to consider when choosing an oat tin can packing machine line is the level of automation that you require. Some packing machine lines are fully automated, while others require more manual intervention. The level of automation that you choose will depend on your production volume, budget, and the level of precision and consistency that you require in your packaging process.

In addition to production capacity and automation level, it is also important to consider the speed and efficiency of the oat tin can packing machine line. A machine line that can pack oat tin cans quickly and efficiently will help to increase productivity and reduce downtime in your production process. It is important to choose a machine line that is reliable and can consistently deliver high-quality packaging results.

Furthermore, it is important to consider the space requirements of the oat tin can packing machine line. You will need to ensure that you have enough space in your production facility to accommodate the machine line and allow for easy access for maintenance and cleaning. It is important to measure the available space in your facility and choose a machine line that fits within those constraints.

When choosing an oat tin can packing machine line, it is also important to consider the cost of the machine line and the return on investment that it will provide for your business. It is important to compare the cost of different machine lines and consider factors such as maintenance costs, energy consumption, and the potential for increased productivity and efficiency in your production process.

In conclusion, choosing the right oat tin can packing machine line for your business is a crucial decision that can have a significant impact on your production process. By considering factors such as production capacity, automation level, speed and efficiency, space requirements, and cost, you can make an informed decision that will help to improve the quality and efficiency of your packaging process. It is important to research different machine lines, consult with industry experts, and carefully evaluate your production needs in order to choose the best oat tin can packing machine line for your business.

Maintenance Tips for Oat Tin Can Packing Machine Line

Maintaining a smooth and efficient oat tin can packing machine line is essential for any food packaging operation. Regular maintenance not only ensures the longevity of the equipment but also helps to prevent costly breakdowns and production delays. In this article, we will discuss some key maintenance tips for keeping your oat tin can packing machine line running smoothly.

One of the most important maintenance tasks for an oat tin can packing machine line is regular cleaning. Over time, dust, debris, and food particles can build up on the equipment, leading to decreased efficiency and potential contamination issues. It is important to clean the machine line thoroughly after each production run, paying special attention to areas where food particles are likely to accumulate. Use a mild detergent and warm water to clean the equipment, and be sure to dry it thoroughly before starting the next production run.

In addition to regular cleaning, it is also important to inspect the oat tin can packing machine line for any signs of wear or damage. Check the conveyor belts, rollers, and other moving parts for any signs of wear, and replace any damaged components as needed. It is also a good idea to lubricate the moving parts of the equipment regularly to ensure smooth operation. Be sure to use the appropriate lubricant for each component, as using the wrong type of lubricant can cause damage to the equipment.

Another important maintenance task for an oat tin can packing machine line is calibrating the equipment regularly. Over time, the settings on the machine line can drift out of alignment, leading to inaccurate packaging and potential product waste. It is important to calibrate the equipment according to the manufacturer’s specifications to ensure accurate and consistent packaging. Keep a record of the calibration settings for each component of the machine line, and be sure to recalibrate the equipment as needed.

In addition to regular cleaning, inspection, and calibration, it is also important to train your staff on proper machine line maintenance procedures. Make sure that your employees are familiar with the equipment and know how to perform basic maintenance tasks such as cleaning, lubricating, and inspecting the machine line. Provide training on how to identify and troubleshoot common issues with the equipment, and encourage your staff to report any maintenance issues promptly.

By following these maintenance tips, you can help to ensure that your oat tin can packing machine line runs smoothly and efficiently. Regular cleaning, inspection, calibration, and staff training are essential for keeping the equipment in good working order and preventing costly breakdowns. Remember to follow the manufacturer’s guidelines for maintenance and consult with a professional if you are unsure about any aspect of machine line maintenance. With proper care and attention, your oat tin can packing machine line can continue to provide reliable packaging for your products for years to come.