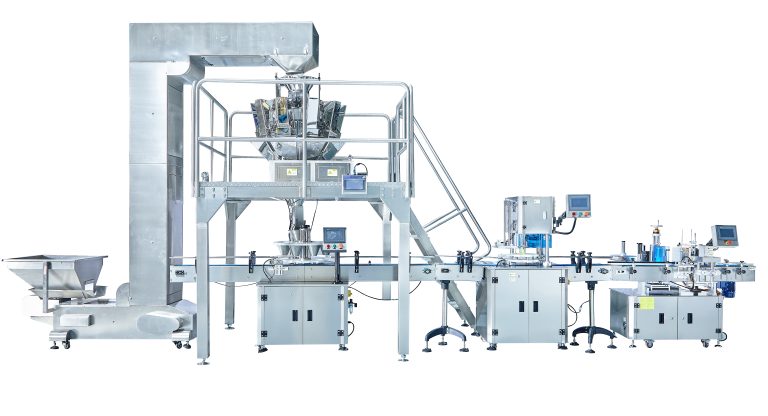

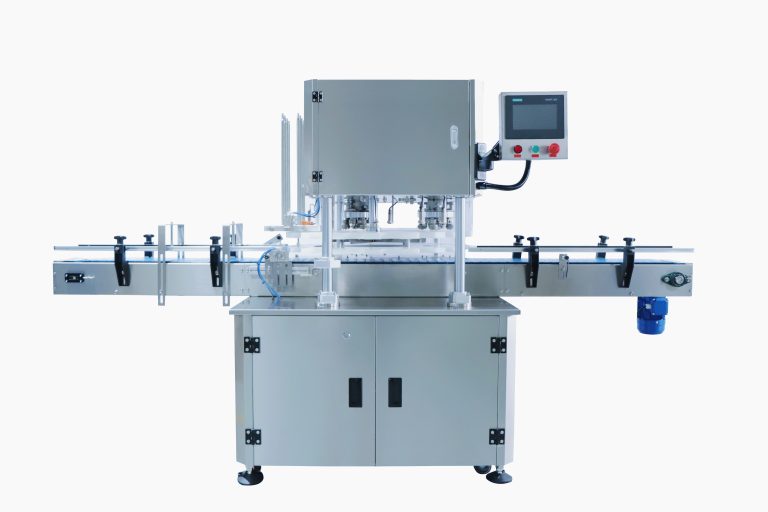

The Automatic Tin Can Flanger Machine is a technological marvel in the world of tin can production.

This advanced Automatic Tin Can Flanger Machine is specifically engineered to perform the crucial task of flanging on tin cans with remarkable precision and efficiency. Flanging is an essential process that adds strength and stability to the can’s edges, ensuring a secure and reliable container.

The automatic operation of the machine eliminates the need for laborious manual processes, significantly increasing production speed and reducing the margin of error. It can handle a large volume of tin cans in a short period, meeting the demands of high-output manufacturing lines.

The Automatic Tin Can Flanger Machine is designed to accommodate various sizes and types of tin cans, offering flexibility to manufacturers. It adjusts seamlessly to different specifications, allowing for a diverse range of can production.

The quality of the flanged edges produced by this Automatic Tin Can Flanger Machine is consistently high. Smooth and uniform flanges not only enhance the appearance of the tin cans but also improve their functionality and durability.

Equipped with intelligent control systems, operators can easily monitor and adjust the machine’s parameters to achieve optimal flanging results. This ensures that each can meets the exacting standards of quality and performance.

The reliability and longevity of the Automatic Tin Can Flanger Machine make it a valuable asset for can manufacturing facilities. It requires minimal maintenance and is built to withstand the rigors of continuous operation.

In conclusion, this Automatic Tin Can Flanger Machine plays a vital role in streamlining the tin can manufacturing process, delivering high-quality products efficiently and contributing to the success of the packaging industry.