Table of Contents

Benefits of Using Automatic Screw Capper Equipment for Snack Food Packaging

In the fast-paced world of snack food production, efficiency and consistency are key factors in ensuring the success of a product. One way to achieve these goals is by utilizing automatic screw capper equipment for packaging. This advanced technology offers a range of benefits that can streamline the packaging process and improve overall product quality.

One of the primary advantages of using automatic screw capper equipment is its ability to increase production speed. Manual capping processes can be time-consuming and labor-intensive, leading to bottlenecks in the production line. By automating the capping process, snack food manufacturers can significantly reduce the time it takes to package their products, allowing for higher output and faster turnaround times.

In addition to speed, automatic screw capper equipment also offers improved accuracy and consistency. Manual capping processes are prone to human error, which can result in improperly sealed packages and product spoilage. Automatic cappers, on the other hand, are programmed to apply the correct amount of torque to each cap, ensuring a secure seal every time. This level of precision not only reduces the risk of product contamination but also enhances the overall quality and shelf life of the snack food.

Furthermore, automatic screw capper equipment can help reduce packaging waste and costs. Manual capping processes often result in over-tightened or under-tightened caps, leading to product leakage and spoilage. This can result in significant financial losses for snack food manufacturers. By using automatic cappers, companies can minimize the risk of product damage and waste, ultimately saving money in the long run.

Another benefit of automatic screw capper equipment is its versatility. These machines can be easily adjusted to accommodate a wide range of cap sizes and types, making them suitable for packaging various snack food products. Whether manufacturers are packaging chips, nuts, or candies, automatic cappers can be customized to meet their specific needs. This flexibility allows companies to adapt to changing market demands and expand their product offerings without investing in additional equipment.

Additionally, automatic screw capper equipment is designed to be user-friendly and easy to maintain. Most machines come equipped with intuitive controls and self-diagnostic features, making them simple to operate and troubleshoot. This reduces the need for specialized training and minimizes downtime due to equipment malfunctions. With proper maintenance and regular servicing, automatic cappers can provide years of reliable performance, ensuring a smooth and efficient packaging process for snack food manufacturers.

In conclusion, the benefits of using automatic screw capper equipment for snack food packaging are clear. From increased production speed and accuracy to reduced waste and costs, these machines offer a range of advantages that can help companies improve their efficiency and product quality. By investing in automatic cappers, snack food manufacturers can stay ahead of the competition and meet the demands of today’s fast-paced market.

How to Choose the Right Automatic Screw Capper Equipment for Your Snack Food Production Line

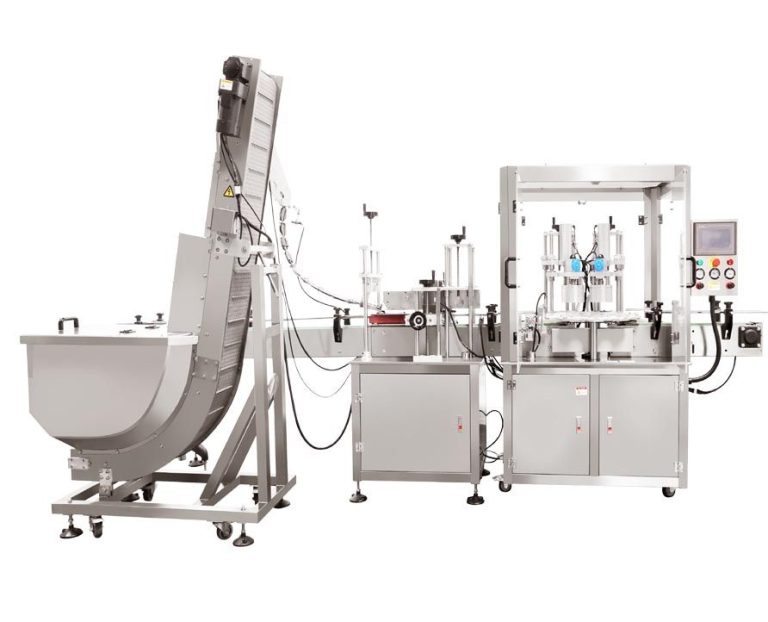

When it comes to snack food production, efficiency and consistency are key factors in ensuring a successful operation. One piece of equipment that can greatly improve the packaging process is an automatic screw capper. This machine is designed to securely seal containers with screw-on caps, providing a tight seal that helps preserve the freshness of the product. However, with so many options available on the market, it can be overwhelming to choose the right automatic screw capper equipment for your snack food production line.

One of the first things to consider when selecting an automatic screw capper is the speed and capacity of the machine. Depending on the size of your production line and the volume of products you need to package, you will need to choose a machine that can keep up with the demand. Look for a screw capper that offers a high speed and can handle a large number of containers per minute to ensure that your production line runs smoothly and efficiently.

In addition to speed and capacity, it is important to consider the size and type of containers that your snack food products are packaged in. Automatic screw cappers come in a variety of sizes and configurations to accommodate different container sizes and shapes. Make sure to choose a machine that is compatible with the containers you use in your production line to ensure a proper fit and seal.

Another important factor to consider when choosing an automatic screw capper is the level of automation and customization that the machine offers. Some machines come with advanced features such as automatic cap feeding, torque control, and adjustable settings for different cap sizes. These features can help improve the efficiency and accuracy of the sealing process, resulting in a higher quality finished product.

When selecting an automatic screw capper for your snack food production line, it is also important to consider the overall reliability and durability of the machine. Look for a machine that is built with high-quality materials and components to ensure long-term performance and minimal downtime. Additionally, consider the reputation of the manufacturer and read reviews from other customers to gauge the reliability of the machine.

Finally, consider the level of support and service that the manufacturer offers. Look for a company that provides training, maintenance, and technical support to help you get the most out of your automatic screw capper equipment. A reliable manufacturer will be able to assist you with any issues or questions that may arise during the operation of the machine, ensuring that your production line runs smoothly and efficiently.

In conclusion, choosing the right automatic screw capper equipment for your snack food production line is a crucial decision that can greatly impact the efficiency and quality of your operation. Consider factors such as speed, capacity, compatibility, automation, reliability, and support when selecting a machine to ensure that you choose the best option for your specific needs. By investing in a high-quality automatic screw capper, you can improve the packaging process and ultimately enhance the overall success of your snack food production line.

Maintenance Tips for Ensuring Optimal Performance of Automatic Screw Capper Equipment in Snack Food Packaging Operations

Automatic screw capper equipment plays a crucial role in the snack food packaging industry, ensuring that products are sealed securely and efficiently. To maintain optimal performance and prolong the lifespan of this equipment, it is essential to follow a regular maintenance routine. In this article, we will discuss some key maintenance tips for automatic screw capper equipment in snack food packaging operations.

One of the most important maintenance tasks for automatic screw capper equipment is regular cleaning. Over time, dust, debris, and food particles can accumulate on the equipment, leading to decreased efficiency and potential malfunctions. It is recommended to clean the equipment after each use, using a mild detergent and water to remove any residue. Additionally, it is important to inspect the equipment for any signs of wear or damage, such as loose screws or worn-out parts, and address these issues promptly to prevent further damage.

Another crucial aspect of maintenance for automatic screw capper equipment is lubrication. Proper lubrication of moving parts is essential to ensure smooth operation and prevent premature wear. It is recommended to use a high-quality lubricant specifically designed for food processing equipment, and to follow the manufacturer’s guidelines for lubrication frequency and quantity. Regular lubrication will help to reduce friction, extend the lifespan of the equipment, and maintain optimal performance.

In addition to cleaning and lubrication, it is important to regularly inspect and adjust the settings of the automatic screw capper equipment. Over time, the settings may become misaligned or out of calibration, leading to issues such as misaligned caps or improper sealing. It is recommended to perform regular checks of the equipment settings, and to make any necessary adjustments to ensure that the equipment is operating correctly.

Furthermore, it is important to train operators on the proper use and maintenance of automatic screw capper equipment. Proper training will help to prevent operator errors and ensure that the equipment is used correctly, reducing the risk of damage and malfunctions. Operators should be familiar with the equipment’s operation manual, and should be trained on how to perform basic maintenance tasks such as cleaning, lubrication, and adjustment of settings.

In conclusion, regular maintenance is essential for ensuring optimal performance of automatic screw capper equipment in snack food packaging operations. By following a regular maintenance routine that includes cleaning, lubrication, inspection, and operator training, you can prolong the lifespan of the equipment, reduce the risk of malfunctions, and ensure that your snack food products are sealed securely and efficiently. Remember to consult the manufacturer’s guidelines for specific maintenance recommendations, and to address any issues promptly to prevent further damage. By taking care of your automatic screw capper equipment, you can ensure that your snack food packaging operations run smoothly and efficiently.