In the realm of packaging machinery, the high speed screw capping machine for plastic containers has emerged as a game-changer.

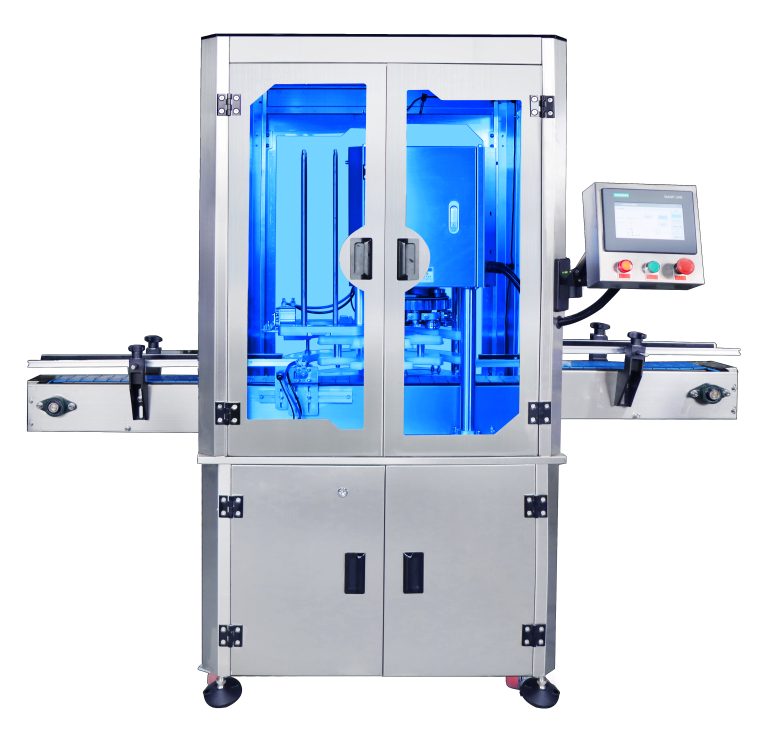

This machine is specifically engineered to handle the capping process of plastic containers at an incredibly high speed. It is capable of screwing caps onto plastic containers with remarkable speed and precision, thereby significantly increasing the packaging line’s productivity.

One of the key features of this high speed screw capping machine is its advanced screw capping mechanism. It applies the right amount of torque and rotational force to ensure a tight and secure cap fit on the plastic container. This helps in preventing leaks and maintaining the product’s integrity during storage and transportation.

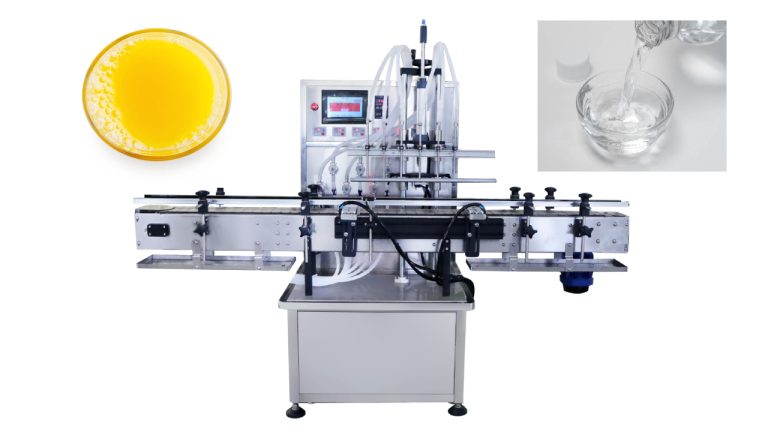

The high speed operation of the machine allows for quick and efficient capping of a large number of plastic containers in a short span of time. This is particularly beneficial in industries where there is a high demand for packaged products and time is of the essence.

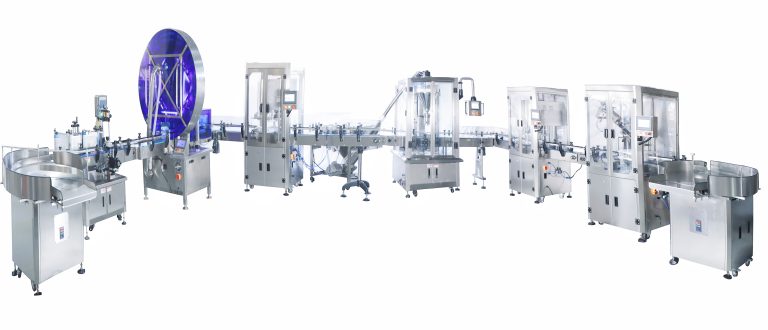

The machine is also highly adaptable and can handle a wide range of cap sizes and styles, making it suitable for various types of products packaged in plastic containers. It can easily be adjusted and calibrated to accommodate different packaging requirements.

In terms of design and construction, the high speed screw capping machine for plastic containers is built with durability and reliability in mind. It is constructed using high-quality materials to withstand the rigors of continuous operation in a production environment.

Overall, this machine is an essential component of any modern packaging setup, enabling manufacturers to achieve faster packaging cycles, improve product quality, and meet the demands of a highly competitive market.