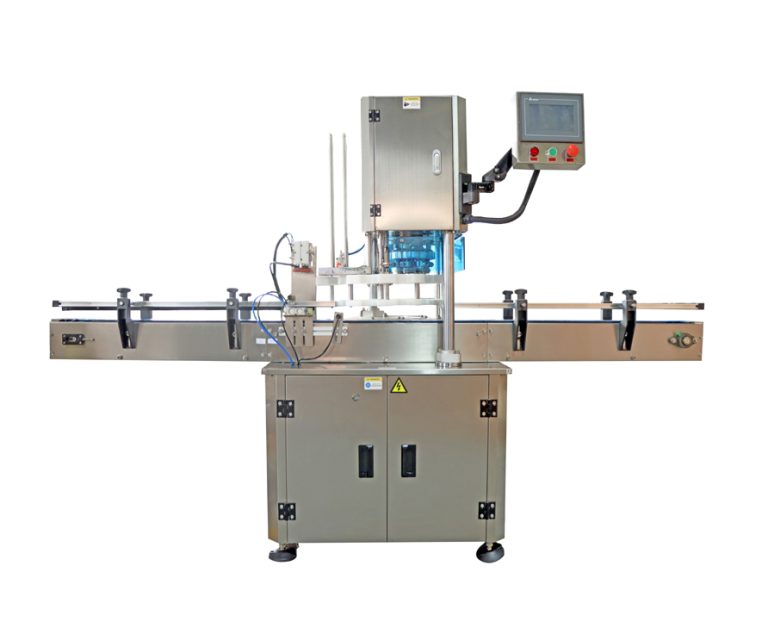

An automatic powder auger filling machine is a specialized piece of equipment designed to accurately and efficiently fill containers with powder substances.

It works through a well-coordinated mechanical process. At the core of the machine is an auger, which is a spiral-shaped component. The powder is fed into a hopper, and as the auger rotates, it moves the powder along its length towards the filling nozzle.

The rotation speed of the auger is precisely controlled by an advanced control system. This control system determines the amount of powder that is dispensed based on pre-set parameters or sensor feedback.

Sensors monitor various factors such as the powder level in the hopper, the pressure within the system, and the filling progress in the containers. This real-time data is used to adjust the auger’s rotation and ensure accurate and consistent filling.

The filling nozzle is designed to direct the powder precisely into the containers, minimizing spillage and ensuring a clean and efficient filling process.

In summary, an automatic powder auger filling machine combines mechanical components like the auger with advanced control and sensing systems to provide a reliable and precise method of filling containers with powder.