Benefits of Using a Paper Tube Flanging and Seaming Machine

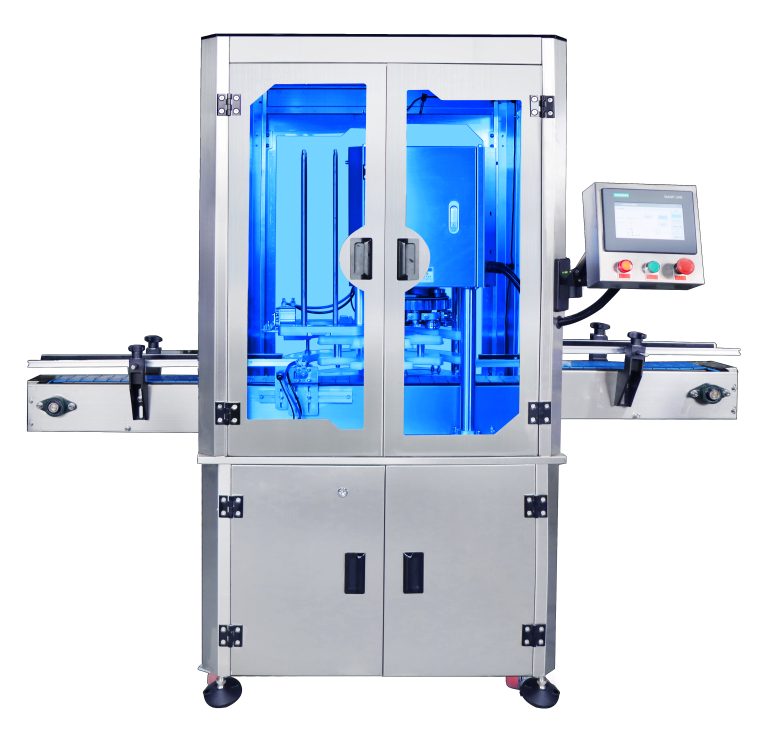

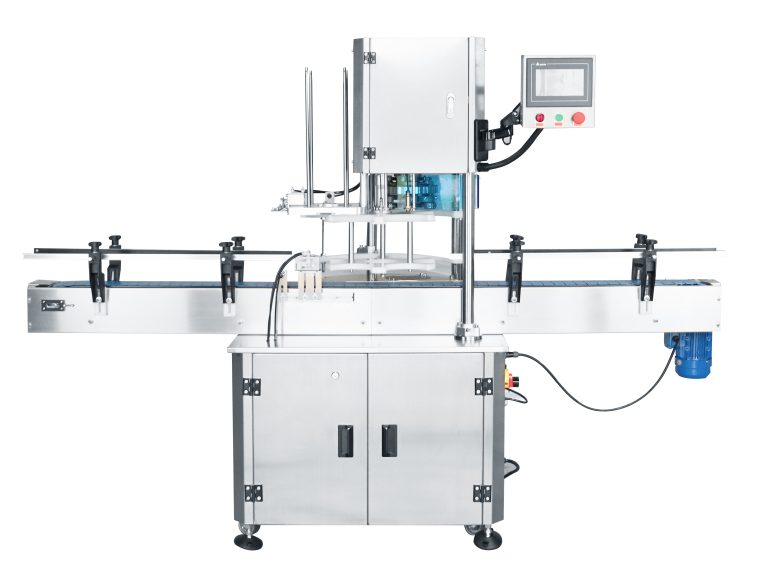

Paper tube flanging and seaming machines are essential equipment in the packaging industry. These machines are designed to efficiently and accurately seal paper tubes, ensuring that the contents are securely contained. There are several benefits to using a paper tube flanging and seaming machine, which we will explore in this article.

One of the primary benefits of using a paper tube flanging and seaming machine is the increase in productivity. These machines are capable of sealing a large number of paper tubes in a short amount of time, significantly reducing the time and labor required for manual sealing. This increase in productivity allows companies to meet their production targets more efficiently and effectively.

.png)

In addition to increased productivity, paper tube flanging and seaming machines also offer improved accuracy and consistency in the sealing process. Manual sealing can be prone to errors and inconsistencies, leading to potential leaks or damage to the contents of the paper tubes. By using a machine, companies can ensure that each paper tube is sealed with precision and uniformity, reducing the risk of defects and ensuring the quality of the final product.

Furthermore, paper tube flanging and seaming machines are designed to be user-friendly and easy to operate. This makes them accessible to a wide range of operators, regardless of their level of experience or expertise. With minimal training, operators can quickly learn how to use the machine effectively, further increasing productivity and reducing the likelihood of errors in the sealing process.

Another benefit of using a paper tube flanging and seaming machine is the cost savings it can provide to companies. While the initial investment in a machine may seem significant, the long-term savings in labor costs and reduced waste can quickly offset this expense. By automating the sealing process, companies can reduce the need for manual labor, saving both time and money in the production process.

Additionally, paper tube flanging and seaming machines are versatile and can be customized to meet the specific needs of different industries. Whether sealing paper tubes for food packaging, textile storage, or industrial applications, these machines can be adjusted to accommodate various tube sizes and sealing requirements. This flexibility allows companies to adapt to changing market demands and expand their product offerings without the need for additional equipment.

Overall, the benefits of using a paper tube flanging and seaming machine are clear. From increased productivity and accuracy to cost savings and versatility, these machines offer a range of advantages to companies in the packaging industry. By investing in a quality machine, companies can streamline their production process, improve the quality of their products, and ultimately enhance their competitiveness in the market.